A hollow fiber system achieves reliable, high-quality filtration through its advanced ultrafiltration membrane design and precise manufacturing process. Engineers use a hollow fiber spinning machine to create membranes that offer consistent contaminant removal. The system maintains high permeate purity, even when water quality fluctuates. Operators trust the system for its ability to deliver low-turbidity permeate and efficient performance. In wastewater treatment, the hollow fiber system removes total coliforms, faecal coliforms, and faecal streptococci with high efficiency. The system adapts to various water sources and consistently produces high-quality permeate in every application.

Key Takeaways

- Hollow fiber system uses advanced membrane technology to consistently remove contaminants, ensuring high-quality water output.

- The unique membrane structure maximizes filtration efficiency, allowing for large volumes of water to be processed with minimal material.

- Regular maintenance and automated cleaning cycles help preserve membrane performance and extend service life, reducing operational costs.

- These systems adapt to various water sources, making them suitable for municipal, industrial, and wastewater treatment applications.

- Hollow fiber ultrafiltration supports sustainable water management by enabling wastewater reuse and reducing untreated water discharge.

Hollow Fiber System Technology

Membrane Structure and Surface Area

Hollow fiber ultrafiltration relies on a unique membrane structure that maximizes filtration efficiency. The membranes feature a high surface area-to-volume ratio, which allows them to process large volumes of water with minimal material. Each hollow fiber module contains thousands of fibers, resulting in hundreds of square meters of filtration area within a compact design. This spacious surface area enables effective contaminant removal and supports high throughput.

- Hollow fiber membranes adapt to different water treatment needs by modifying pore sizes or adding filtration layers.

- Cross-flow filtration configurations increase fluid contact with the membrane, enhancing ultrafiltration performance.

- A single module can contain thousands of fibers, providing significant filtration area and boosting overall efficiency.

Increasing the membrane surface area from 1.0 to 1.8 m² extends filter lifetime and improves contaminant removal rates. Filters with larger membrane areas show higher protein adsorption, which demonstrates the direct relationship between surface area and filtration quality. Ultrafiltration membranes offer flexibility for municipal water treatment, biopharmaceutical production, and advanced purification processes.

Tip: The compact footprint of hollow fiber ultrafiltration systems makes them ideal for facilities with limited space while maintaining high contaminant clearance.

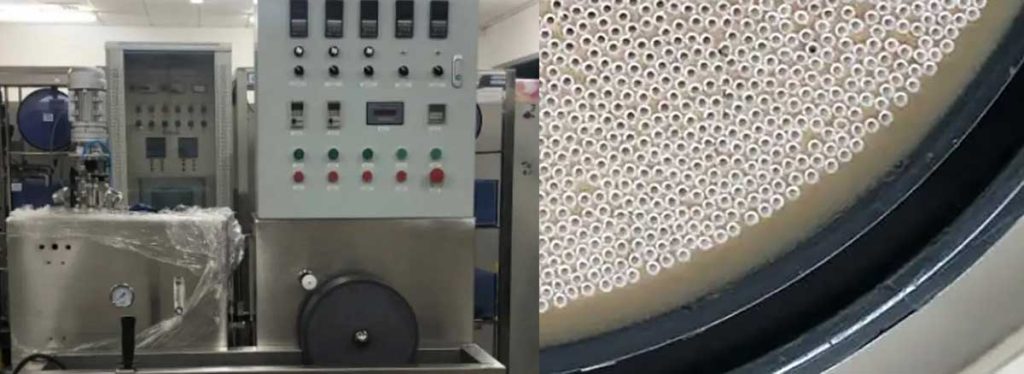

Role of the Hollow Fiber Spinning Machine

The hollow fiber spinning machine plays a critical role in producing ultrafiltration membranes with consistent quality. Manufacturers control parameters such as temperature, pressure, polymer concentration, and spinning speed to ensure uniform fiber formation. Even minor variations can affect membrane performance, so advanced automation technologies maintain strict production standards.

| Parameter | Impact On Membrane Quality |

|---|---|

| Temperature | Influences polymer viscosity and fiber formation |

| Pressure | Affects density and structure of the membrane |

| Polymer Concentration | Determines pore size and mechanical strength |

| Spinning Speed | Impacts uniformity and consistency of fibers |

Quality control measures, including bubble-point testing and automated integrity systems, verify membrane reliability. Control systems using artificial intelligence help manufacturers anticipate defects and minimize downtime. These technologies allow for tighter tolerances, which are essential for producing high-performance ultrafiltration membranes. The hollow fiber membrane spinning machine ensures that each membrane meets strict standards for filtration consistency, supporting reliable operation in diverse applications.

Ultrafiltration Mechanism and Consistency

Physical Barrier for Contaminant Removal

Ultrafiltration systems use hollow fiber membranes to create a physical barrier that separates contaminants from water. The membrane structure features pores ranging from 0.01 to 0.1 microns. These pores block suspended solids, bacteria, protozoa, some viruses, colloids, and high molecular weight organic compounds. The membrane consistently produces high-quality effluent, even when raw-water quality changes.

| Property | Description |

|---|---|

| Pore Size | Typically ranges from 0.01 to 0.1 microns, effective in removing contaminants |

| Contaminants Removed | Suspended solids, bacteria, protozoa, some viruses, colloids, high molecular weight organic compounds |

| Consistency | Provides high-quality effluent regardless of raw-water quality variations |

Laboratory tests show that ultrafiltration achieves near-complete removal of bacteria such as E. coli. Most undiluted permeate samples contain no detectable colonies. One sample reached a log concentration of 0.18, resulting in a log removal value of 6.88. Pilot scale tests confirm that all samples show no presence of E. coli, demonstrating the effectiveness of the membrane. The system also reduces organic matter, as indicated by a decrease in UV254nm absorbance. This result suggests strong potential for larger-scale applications.

Ultrafiltration stands out among membrane filtration technologies for its contaminant removal efficiency. The following chart compares pathogen removal efficiency for ultrafiltration, nanofiltration, and microfiltration:

| Membrane Technology | Pathogen Removal Efficiency (LRV) | Mechanisms of Removal |

|---|---|---|

| Ultrafiltration | 0.5–5.9 log | Size exclusion, Electrostatic interaction |

| Nanofiltration | 4.1–7.0 log | Size exclusion, Electrostatic interaction |

| Microfiltration | 0.7–4.6 log | Size exclusion |

Ultrafiltration membranes have smaller pore sizes than microfiltration, making them more effective for removing bacteria and viruses. Electrostatic interactions further enhance removal rates, especially for viruses. Microfiltration offers better water permeability and fouling mitigation, but ultrafiltration provides superior contaminant removal.

Stable Performance in Challenging Conditions

Ultrafiltration systems maintain stable performance under variable feedwater quality and pressure fluctuations. Advanced membrane chemistry delivers reliable operation without frequent chemical cleaning. Automated cleaning sequences keep the membrane clean during high turbidity events, reducing downtime. High solids tolerance allows the system to produce consistent permeate quality after storm events. Robust cartridge design minimizes damage and contamination, improving system uptime and capacity.

| Feature | Benefit |

|---|---|

| Advanced membrane chemistry | Delivers stable performance without extensive chemical cleans. |

| Automated cleaning sequences | Keeps the membrane clean during difficult turbidity events, reducing downtime. |

| High solids tolerance | Produces consistent permeate quality even after significant storm events. |

| Robust cartridge design | Minimizes damage and contamination, improving system uptime and capacity. |

Ultrafiltration technology adapts to diverse source waters, including surface water, sea water, and wastewater. The system reduces the risk of particle carry-over seen in conventional filtration. Operators rely on ultrafiltration for its ability to handle varying feed water qualities.

- Hydraulic backwashing reverses flow from the permeate side to the feed side, loosening and removing foulant layers. This process reduces reversible fouling.

- Typical backwashing pressure and flux values in ultrafiltration systems for drinking water production range from 1.0 to 1.5 bar and 230 to 300 L/m² h.

- Air backwashing consumes energy similar to conventional processes, supporting efficient operation.

Pilot projects illustrate the consistent operation of hollow fiber ultrafiltration systems under challenging conditions. One study focused on a rotating hollow fiber membrane for direct filtration of domestic wastewater. The membrane operated effectively with permeate fluxes of 24–30 L/hm². Cleaning methods included gas sparging and rotation, with rotation proving more effective in reducing fouling. Long-term trials demonstrated up-concentration of municipal wastewater up to 12 times, with a net permeate flux of 20 L/hm². Suspended solids concentrations reached 5750 mg/L, and volatile suspended solids reached 4750 mg/L, leading to reversible cake formation on the membrane surface. Energy consumption remained low at 0.027 kWh/m³.

Ultrafiltration consistently removes bacteria and viruses, even when feedwater contains high levels of contaminants. The membrane structure and operational features ensure reliable removal of bacteria, viruses, and particulates. Operators achieve stable performance and high-quality permeate, regardless of environmental or operational challenges.

Filtration Quality and Real-World Results

High Clearance and Low Fouling Rates

Hollow fiber ultrafiltration systems deliver high-quality water by maintaining low fouling rates and effective contaminant clearance. Operators monitor transmembrane pressure, flux decline, and permeability to optimize cleaning intervals. Regular cleaning cycles help preserve membrane performance and extend service life. Specialized chemical solutions target specific foulants, such as acidic mixtures for inorganic scaling and alkaline formulas for organic fouling. Physical cleaning methods, including air scouring, backwashing, and relaxation, remove foulants and reduce chemical usage. These strategies ensure that the water treatment process remains efficient and produces high-quality permeate.

- Cleaning frequency adapts to operational needs, minimizing energy consumption.

- Pressure drop and permeate flux decline trigger cleaning cycles, maintaining filtration quality.

- Physical cleaning techniques support membrane longevity and consistent output.

Operators achieve high clearance rates for bacteria, viruses, and suspended solids. The ultrafiltration membrane structure blocks contaminants and supports the production of high-quality water. Consistent permeate quality results from careful monitoring and maintenance.

Consistent Output Across Applications

Hollow fiber ultrafiltration systems provide reliable filtration quality across diverse water sources and application scales. The membrane design supports adaptability in municipal, industrial, and wastewater treatment settings. Pilot tests and industrial studies confirm stable performance under varying feedwater conditions.

| Evidence Description | Key Points |

|---|---|

| Advantages of Hollow Fiber Membranes | Lower fouling tendencies, effective hydraulic cleaning, high contaminant removal rates |

| Performance in SULEMAN Project | Achieved 90% MgSO4 retention, stable sulfate removal |

| Comparison with Spiral-Wound Membranes | Better cleaning effectiveness, reduced fouling due to absence of feed spacers |

Operators report low-turbidity and low-SDI permeate, even when feedwater quality fluctuates. The Aromatec module achieved up to 90% feed recovery, demonstrating adaptability. Stable water flux and effective chemical cleaning methods support consistent permeate quality. The technology minimizes wastewater volumes and maintains high-quality water output.

Note: Hollow fiber ultrafiltration systems adapt to different water treatment process requirements, ensuring high-quality permeate and reliable filtration quality in every application.

Handling Operational Challenges

Managing High Solids and Sludge

Hollow fiber ultrafiltration systems face several operational challenges in municipal and industrial settings. Operators often encounter fouling, regulatory compliance issues, and the need to maintain high flux rates while controlling maintenance costs. Innovations in membrane materials, such as superhydrophilic coatings, have helped reduce fouling and improve system reliability.

When treating wastewater with high solids or sludge, hollow fiber systems demonstrate strong adaptability. The following table summarizes key observations from studies on membrane performance during periods of elevated mixed liquor suspended solids (MLSS):

| Parameter | Observation |

|---|---|

| MLSS Range | 8 to 32 g L−1 |

| Permeability Loss | Marginal loss between 8 and 18 g L−1 |

| Clogging Impact | Significant above 18 g L−1 |

| Sustainable Flux | Dependent on MLSS and membrane condition |

Operators report high permeate quality, with nearly complete removal of ammonia, BOD, and suspended solids from wastewater. Average COD removal reaches 91%, although variability occurs due to soluble microbial products and extracellular polymeric substances. Clogging risk increases with poor sludge quality and higher operational flux, but system design features help mitigate these effects.

Several strategies support clogging prevention and throughput maintenance:

| Strategy | Description |

|---|---|

| Single-potted cartridge | Design without a bottom header allows better air scouring |

| Loose fiber configuration | Hanging fibers enhance air scouring effectiveness |

| Chemical cleaning management | Intensive cleaning addresses fouling from high solids |

Operators select hydrophilic PVDF fibers for easy cleaning and wettability. The outside-in flow configuration tolerates variable feed water qualities, and system designs allow for integrity testing and straightforward maintenance.

Maintaining Quality Under Stress

Hollow fiber ultrafiltration systems maintain consistent water and wastewater quality even during periods of fluctuating feedwater conditions or increased demand. Modular designs enable scalability and customization for different applications. Automation and digital integration improve process control, reduce errors, and lower operational costs.

Maintenance requirements play a crucial role in ensuring system performance. Operators monitor transmembrane pressure, crossflow velocity, and temperature to optimize cleaning intervals. Air scour cleaning and easy air removal during maintenance help preserve membrane integrity. The following table outlines typical maintenance aspects:

| Maintenance Aspect | Description |

|---|---|

| Membrane Selection | Enhanced fouling resistance with hydrophilic coatings |

| Cleaning | Air scour cleaning and easy air removal during cleaning |

| Operational Parameters | Maintain appropriate pressure, velocity, and temperature |

Cost factors include maintenance expenses due to fouling, membrane fragility, and the high cost of raw materials. Operators address these challenges by choosing robust membranes and implementing efficient cleaning protocols.

The system’s efficiency, scalability, and adaptability allow it to handle high solids, sludging, and fluctuating feedwater in both water and wastewater treatment. Operators achieve reliable contaminant removal and consistent permeate quality, supporting regulatory compliance and operational goals.

Tip: Modular hollow fiber systems can expand capacity quickly to meet changing water and wastewater treatment needs.

- Operators benefit from low-turbidity water and stable wastewater output, even under stress.

- System designs support easy maintenance and long-term reliability.

Conclusion

Hollow fiber ultrafiltration systems deliver consistent, high-quality water filtration through advanced membrane technology, precise manufacturing, and robust operational features. These systems reliably remove contaminants from water, supporting both upstream and downstream bioprocessing. Operators benefit from modular designs that adapt to different water sources and process scales. The membranes, made from PVDF, withstand harsh water conditions and maintain performance. Regular integrity testing and predictive maintenance help mitigate common failure modes, ensuring safe water output. Experts recognize hollow fiber ultrafiltration for providing cost-effective, dependable access to clean water. The technology protects water ecosystems by reducing untreated water discharge and supports sustainable water reuse. Companies meet stringent water quality standards, reinforcing the credibility of hollow fiber system. The expansion of compact systems in rural areas highlights their effectiveness in delivering safe water. Choosing hollow fiber ultrafiltration ensures reliable water purification for diverse needs.

FAQ

What Makes Hollow Fiber System Deliver Consistent Water Quality?

Hollow fiber system uses precise membrane engineering and automated controls. These features help maintain consistent water quality by removing particles and microorganisms. Operators monitor performance with sensors and adjust cleaning cycles as needed.

How Do Hollow Fiber Membranes Support Potable Water Treatment?

Hollow fiber membranes remove bacteria, viruses, and suspended solids. This process ensures safe drinking water. Many municipal plants use these membranes for potable water treatment because they provide reliable results and meet strict health standards.

Can Hollow Fiber System Enable Wastewater Reuse?

Yes. Hollow fiber system filters contaminants from treated wastewater. This process allows facilities to use the water again for irrigation, industrial processes, or groundwater recharge. Wastewater reuse helps conserve resources and supports sustainable water management.

Are Hollow Fiber Systems Suitable for Advanced Water Treatment?

Engineers use hollow fiber systems in advanced water treatment applications. These systems handle challenging feedwater and remove fine particles. Operators choose them for desalination pretreatment, pharmaceutical production, and high-purity water systems.

What Maintenance Do Hollow Fiber Systems Require?

Operators perform regular cleaning, monitor transmembrane pressure, and inspect membranes for damage. Scheduled maintenance helps prevent fouling and extends membrane life. Most systems include automated cleaning features to reduce manual labor.