PLC control drives remarkable advances in hollow fiber spinning machine. Industry reports highlight how this system maintains accurate flow rates, which leads to consistent fiber diameters and reliable product quality. Automation through PLC control supports continuous production and adapts to various polymers, making the system more efficient. The system reduces labor costs by minimizing manual intervention. Operators see improved efficiency, less downtime, and enhanced reproducibility thanks to the system’s advanced control capabilities. Each system upgrade with PLC control brings measurable gains in spinning output and product consistency.

Key Takeaways

- PLC control automates the spinning process, reducing manual adjustments and minimizing human error.

- Real-time monitoring and feedback from sensors ensure consistent fiber quality and production efficiency.

- Predictive maintenance features help detect issues early, reducing downtime and extending equipment life.

- Adjustable parameters for flow, temperature, and speed lead to high-quality, uniform fibers with fewer defects.

- Upgrading to PLC systems can lower labor costs and improve overall production reliability and efficiency.

PLC Control in Hollow Fiber Spinning Machine

Core Functions and Automation

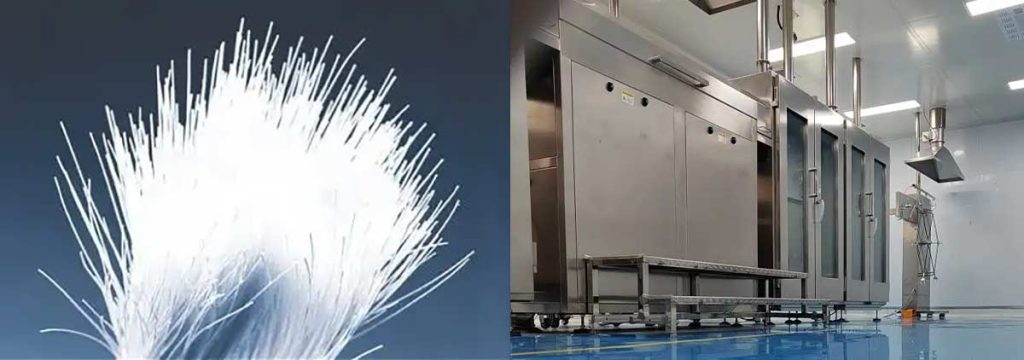

PLC, or programmable logic controllers, serve as the central brain of a hollow fiber membrane spinning machine. These controllers manage every aspect of the spinning process, from the initial polymer feed to the final fiber winding. PLC control ensures that each step follows precise instructions, which leads to consistent fiber quality and reliable production. Operators use a PLC based control system to automate tasks that once required manual adjustments. This automation increases efficiency and reduces the risk of human error.

A PLC based control system allows for real-time adjustments during spinning. The system can change flow rates, temperatures, and pressures instantly. This flexibility supports industrial automation and helps maintain tight tolerances. Hollow fiber spinning machine relies on PLC to synchronize multiple motors, pumps, and valves. The result is a process that produces uniform fibers with minimal variation. Industrial automation through PLC also improves safety by monitoring critical parameters and shutting down the system if problems occur.

Communication and Sensor Integration

Modern PLC systems use advanced communication protocols like RS485 to connect with sensors and other devices. This network enables the system to collect data from every part of the spinning line. Sensors measure temperature, pressure, and flux in real time. The PLC receives this data and uses feedback loops to adjust the process instantly. This technology keeps the spinning process stable and efficient.

Advanced sensors provide several benefits:

- Real-time monitoring and data analysis for process optimization.

- Immediate adjustments to maintain optimal conditions for membrane production.

- High-precision feedback that reduces defect rates, sometimes by up to 40%.

AI-based control systems can predict defects and reduce downtime. Tighter tolerance levels improve manufacturing precision. The combination of PLC, sensor integration, and communication technology transforms the automated machine into a smart production system. This approach ensures high-quality output and maximizes efficiency throughout the production process.

PLC Features Optimizing the Spinning Process

Precision in Flow and Temperature Control

PLC technology brings a new level of accuracy to the hollow fiber spinning machine. Programmable logic controllers manage the flow of polymer solutions with exact precision. Operators set specific parameters for each production batch. The system uses sensor feedback to monitor flow rates and temperature at every stage. This control ensures that the polymer maintains the correct viscosity, which is essential for membrane production.

The system adjusts heating and cooling automatically. This automation keeps the extrusion and coagulation baths at optimal temperatures. Consistent temperature control prevents defects and supports uniform fiber formation. The system responds instantly to any changes detected by sensors. This rapid feedback loop maintains stability and improves product quality.

Note: PLC control reduces the risk of uneven wall thickness and fiber deformation. The system maintains tight tolerances, which leads to reproducible results in membrane production.

Speed Regulation and Motor Efficiency

PLC control of induction motor systems plays a critical role in spinning operations. The system regulates motor speed with high accuracy. Operators can program the desired speed for each production run. The system uses feedback from sensors to adjust motor output in real time. This control of induction motor speed ensures that the spinning process remains stable.

Industrial automation through PLC improves motor efficiency. The system synchronizes multiple motors and actuators, which reduces energy consumption. Efficient motor control supports continuous production and minimizes downtime. The system detects any irregularities in motor performance and alerts operators immediately. This proactive approach protects equipment and maintains fiber strength.

A well-regulated motor system contributes to consistent fiber diameter. The system prevents fluctuations that could affect fiber structure. Reliable speed control supports high-quality membrane production and enhances overall efficiency.

Spinneret Design and Fiber Structure

PLC control influences design of hollow fiber spinneret and the resulting fiber structure in several ways:

- Operators set specific production parameters for different fiber types, such as medical-grade or industrial-grade fibers.

- The system manages the temperature of the extrusion system and coagulation bath, which maintains polymer viscosity and supports solidification.

- Automated controls adjust heating and cooling to create uniform and durable hollow fiber structures.

- The system regulates flow rates through the spinneret using sensor feedback and actuators, which prevents defects like uneven wall thickness.

The impact of PLC features on fiber diameter, structure, and product quality can be seen in technical studies:

| Parameter | Effect on Fiber Diameter and Quality |

|---|---|

| PCL Concentration | Optimal concentration of 11.85 wt% produced micro-nano fibers with diameters between 1185.17 to 1338.69 nm. |

| Voltage | A voltage of 13.05 kV was found to be effective in controlling fiber diameter. |

| Distance | A distance of 82.17 cm was identified as optimal for achieving desired fiber characteristics. |

| Morphology | Bead-free micro-nano fibers were formed at concentrations above 12.50 wt%, while lower concentrations resulted in bead formation. |

| Structural Analysis (FTIR) | Presence of alkane, ester, and ether functional groups indicates molecular integrity, crucial for product quality. |

PLC control allows for precise adjustment of these parameters. The system maintains optimal conditions for membrane production. Operators achieve consistent fiber diameter and structure. The system supports the formation of strong, bead-free fibers with reliable molecular integrity. This technology ensures that each production batch meets strict quality standards.

Production Benefits with PLC Systems

Consistency and Quality in Production

PLC control transforms the hollow fiber spinning machine into a reliable tool for membrane production. Operators see consistent fiber diameter and membrane strength in every batch. Programmable logic controllers manage each step of the process, using sensor feedback to adjust parameters instantly. This approach ensures that the system maintains high quality and reproducibility. Manual systems often struggle with variation in fiber structure and filtration performance. PLC automation eliminates these inconsistencies by providing precise control over flow, temperature, and speed. The result is a stable production environment that meets strict quality standards for membrane and fiber products.

Labor Cost Reduction and Error Minimization

PLC control reduces labor costs by automating repetitive tasks. Operators no longer need to adjust settings manually throughout the production cycle. The system handles parameter changes, monitors sensor data, and provides real-time feedback. This automation lowers the risk of human error, which can lead to defects or downtime. In a manual setup, errors in fiber spinning or membrane production can cause significant material loss. PLC-based systems minimize these risks by using feedback loops and predictive analytics. The system alerts operators to potential issues before they affect production speed or quality. Companies achieve high efficiency and reduce operational expenses with this approach.

Maintenance and Downtime Improvements

PLC systems support predictive maintenance, which keeps the hollow fiber spinning machine running smoothly. The system uses sensor integration and software analytics to monitor vibration signatures and lubrication cycles. This monitoring helps operators detect mechanical issues early, reducing unplanned repairs. Predictive maintenance strategies outperform traditional corrective maintenance, which often leads to longer downtime and higher costs. PLCs enable real-time diagnostics and fault alerts, allowing for quick intervention. The system’s proactive approach extends equipment life and maintains fiber strength.

- Predictive maintenance allows for early detection of potential issues, reducing unplanned repairs.

- Integration of sensors and software analytics supports stable performance and minimizes downtime.

- Monitoring vibration signatures helps in identifying mechanical issues before they lead to failures.

- Tracking lubrication cycles ensures that machines operate smoothly, reducing wear and tear.

PLCs may require higher initial investment, but they lower ongoing costs related to wiring, software, and IT management. Their ability to streamline processes and minimize downtime leads to better returns on investment. Real-time monitoring and optimization algorithms also help reduce energy consumption, supporting high efficiency in membrane production. Companies that adopt PLC control see measurable improvements in production needs, reliability, and overall system performance.

Conclusion

PLC control transforms the hollow fiber spinning machine into a modern, efficient tool for production. This system delivers precise control, real-time monitoring, and reliable automation. Industry experts highlight key features and benefits:

| Feature | Benefit |

|---|---|

| PLC control & real-time monitoring | Enhances automation and efficiency |

| Adjustable blending ratio | Allows for precise control in fiber processing |

| Energy-efficient designs | Reduces operational costs and environmental impact |

| Dust-free, closed-loop air system | Improves safety and air quality |

Companies that upgrade to plc systems achieve higher production quality and consistent results.

FAQ

What Is the Main Role of PLC in Hollow Fiber Spinning Machine?

PLC acts as the central controller in the hollow fiber spinning machine. It manages every process step. Operators use PLC to set parameters. The control ensures that the system produces consistent fibers. Plc also helps maintain safety and efficiency during production.

How Does PLC Control Improve Product Quality?

PLC control uses sensor feedback to adjust flow, temperature, and speed. The system responds instantly to changes. This control keeps fiber diameter and structure consistent. Operators see fewer defects. The system ensures that each batch meets strict quality standards.

Can PLC Control Reduce Labor Costs?

PLC control automates many tasks. The system handles parameter changes and monitors sensor data. Operators spend less time on manual adjustments. This control reduces errors and material waste. Companies see lower labor costs and higher efficiency with plc-based systems.

What Maintenance Benefits Does PLC Control Offer?

PLC control supports predictive maintenance. The system monitors vibration and lubrication cycles. Operators receive alerts before problems occur. This control reduces unplanned downtime. The system extends equipment life and keeps production running smoothly.