Hollow fiber perfusion has revolutionized bioprocessing by enabling scalable and efficient production of biopharmaceuticals. Its diverse applications, such as monoclonal antibody production and virus amplification, demonstrate its versatility. Recent advancements highlight its cost efficiency. For instance, small bioreactors now expand 6 million T cells to over 2 billion in just 8 days, while reducing media usage by up to 70%. Continuous perfusion feeding further enhances scalability, allowing expansion beyond 2 billion cells with 95% viability. This innovative approach supports higher yields and reduces resource consumption, making it indispensable in modern biomanufacturing.

Key Takeaways

- Hollow fiber perfusion helps make medicines by growing more cells and giving them nutrients all the time. This increases production.

- This method uses fewer resources, needing up to 70% less material than older ways.

- Hollow fiber bioreactors are used for making antibodies, proteins, and growing stem cells. They are very useful in medicine-making.

- These systems can grow bigger to make more products, saving money and space.

- Running hollow fiber system all the time reduces breaks and increases work, helping create new ideas in medicine production.

Understanding Hollow Fiber Perfusion

Core Principles of Hollow Fiber Perfusion

Hollow fiber perfusion operates on the principle of separating cells from the culture medium using a hollow fiber membrane. This membrane allows nutrients and gases to pass through while retaining cells and larger molecules. The process ensures continuous nutrient delivery and waste removal, creating an optimal environment for cell growth. Unlike traditional batch cultures, hollow fiber bioreactors enable higher cell densities and sustained productivity over extended periods.

Several key parameters define the operational framework of hollow fiber perfusion bioreactor. These include cell density, medium flow rate, cellular matrix thickness, and oxygen concentration. Each parameter plays a critical role in maintaining cell viability and maximizing yields. For example, higher cell densities improve productivity but require precise control of nutrient distribution and oxygen levels. The table below summarizes these parameters:

| Parameter | Description |

|---|---|

| Cell Density | The number of cells per unit volume, influencing nutrient uptake and tissue growth. |

| Medium Flow Rate | The rate at which the culture medium is circulated, affecting mass transfer and nutrient delivery. |

| Cellular Matrix Thickness | The thickness of the matrix surrounding the cells, impacting nutrient diffusion and cell behavior. |

| Oxygen Concentration | Levels of oxygen available to cells, crucial for cellular respiration and growth. |

Mass transfer and nutrient distribution are also critical concepts in hollow fiber perfusion. Efficient mass transfer ensures that nutrients reach all cells, while proper nutrient distribution supports uniform cell growth. These factors, combined with optimized operating parameters, make hollow fiber perfusion a cornerstone of modern bioprocessing.

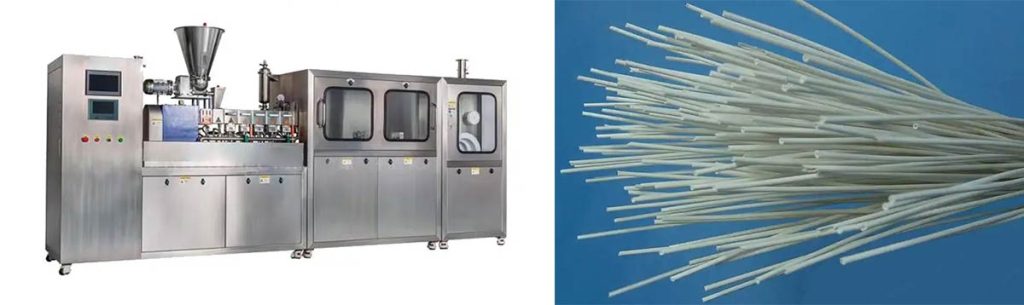

Role of Hollow Fiber Spinning Machine in Bioprocessing

The hollow fiber spinning machine plays a pivotal role in manufacturing hollow fiber filters used in bioreactors. This machine produces hollow fibers with precise pore sizes and structural integrity, ensuring consistent performance in perfusion bioreactors. The quality of these fibers directly impacts the efficiency of nutrient exchange and waste removal.

Hollow fiber spinning machine enables the production of membranes tailored to specific applications. For instance, membranes designed for continuous perfusion must balance permeability and selectivity to maintain optimal cell culture conditions. Advances in spinning technology have improved the scalability of hollow fiber bioreactors, making them suitable for large-scale biopharmaceutical production.

By enabling the production of high-quality hollow fiber membranes, spinning machines contribute to the success of hollow fiber perfusion systems. Their role underscores the importance of precision engineering in bioprocessing, where even minor variations can affect outcomes.

Key Applications of Hollow Fiber Bioreactor

Monoclonal Antibody Production

Hollow fiber perfusion bioreactor has transformed monoclonal antibody production by enabling higher cell density and improved productivity. The bioreactor provides a controlled environment where cells can thrive, ensuring consistent and scalable antibody yields. The hollow fiber filters within the system allow for efficient nutrient exchange and waste removal, which supports continuous perfusion and long-term cell culture.

The ability to maintain high cell density is a critical advantage in monoclonal antibody production. Hollow fiber perfusion systems achieve this by separating cells from the culture medium while continuously supplying nutrients. This process reduces contamination risks and minimizes labor-intensive interventions. Furthermore, the scalability of these bioreactors makes them suitable for both research and industrial-scale antibody production.

Hollow fiber perfusion also enhances the quality of monoclonal antibodies. By providing a stable environment, these systems ensure uniform post-translational modifications, which are essential for the therapeutic efficacy of antibodies. This combination of high yield, quality, and scalability underscores the importance of hollow fiber perfusion in modern biomanufacturing.

Recombinant Protein Production

Recombinant protein production benefits significantly from the unique capabilities of hollow fiber perfusion bioreactor. These systems enable higher concentrations of proteins compared to traditional methods. For example, a 1-liter hollow fiber bioreactor can produce over 10 grams of protein per day while consuming approximately 100 liters of medium. In contrast, standard stirred reactors typically achieve only 1 gram per liter.

The design of hollow fiber bioreactor supports continuous production, which reduces downtime and increases overall productivity. By maintaining a three-dimensional environment that mimics in vivo conditions, these systems enhance cell growth and protein expression. This approach also minimizes contamination from serum and intracellular proteins, resulting in purer products.

Another advantage lies in the ability to control culture parameters precisely. Hollow fiber perfusion allows for easy monitoring and adjustment of factors such as oxygen concentration and nutrient flow. This level of control ensures optimal conditions for protein production, leading to improved productivity and consistency.

Virus Amplification

Virus amplification is another critical application of hollow fiber bioreactor. These systems provide an ideal environment for virus propagation by supporting high cell density and efficient nutrient exchange. The hollow fiber spinning machine plays a vital role in producing the membranes that enable this process, ensuring the structural integrity and performance of the bioreactor.

Hollow fiber perfusion bioreactor excels in amplifying viruses for vaccine production and gene therapy applications. The ability to maintain continuous perfusion reduces the risk of contamination and supports long-term culture. Additionally, the three-dimensional structure of the bioreactor mimics in vivo conditions, enhancing virus yield and quality.

The scalability of hollow fiber bioreactors makes them particularly valuable for large-scale virus production. Researchers can easily adjust the size of the system to meet specific requirements, from laboratory studies to industrial manufacturing. This flexibility, combined with the ability to produce high-quality viruses, highlights the significance of hollow fiber perfusion in advancing virology and biopharmaceutical development.

Stem Cell Culture

Stem cell culture represents one of the most promising applications of hollow fiber perfusion. This method provides an optimal environment for cell growth and proliferation, making it ideal for expanding stem cells for research, therapeutic, and industrial purposes. Hollow fiber cartridges play a crucial role in creating a controlled microenvironment that mimics in vivo conditions, ensuring the viability and functionality of stem cells.

One of the key benefits of perfusion bioreactors in stem cell culture is their ability to maintain a continuous nutrient supply. This feature supports sustained cell growth over extended periods, which is essential for achieving high cell culture density. Unlike traditional batch systems, a continuous perfusion culture system ensures that waste products are efficiently removed while fresh nutrients are consistently delivered. This process minimizes stress on the cells and promotes their proliferation.

Large-scale perfusion bioreactors have revolutionized stem cell production by offering scalability for various applications. Researchers can now expand stem cells in large quantities without compromising their quality. This scalability is particularly valuable for regenerative medicine, where large-scale cell culture is often required to meet clinical demands. The ability to scale up production while maintaining cell integrity highlights the transformative potential of hollow fiber perfusion in this field.

Another advantage of hollow fiber perfusion is its contribution to improved productivity. By enabling higher cell densities and continuous operation, this technology reduces the time and resources needed for stem cell expansion. For example, a single bioreactor can produce billions of stem cells in a fraction of the time required by traditional methods. This efficiency not only accelerates research but also lowers production costs, making stem cell therapies more accessible.

The hollow fiber spinning machine plays an essential role in manufacturing the membranes used in these bioreactors. The machine ensures that the hollow fiber cartridges meet the precise specifications needed for stem cell culture. The quality of these membranes directly impacts the performance of the bioreactor, influencing factors such as nutrient exchange and waste removal. Advances in spinning technology have further enhanced the scalability and efficiency of hollow fiber perfusion systems.

Comparing Perfusion Bioreactor to Traditional Methods

Batch Culture vs. Hollow Fiber Perfusion

Batch culture methods have long been the standard in bioprocessing, offering simplicity and ease of use. However, hollow fiber perfusion systems outperform batch cultures in several key areas. Hollow fiber perfusion enables higher cell density, reaching up to 7.4 × 10^7 cells/mL compared to batch culture’s 2 × 10^7 cells/mL. This increase in cell density directly enhances productivity, making hollow fiber systems ideal for large-scale applications.

The continuous nutrient supply in hollow fiber perfusion supports sustained cell growth and proliferation, unlike batch systems that rely on an initial base medium. Comparative studies show that hollow fiber system produces up to 11.4 grams of antibodies, while batch cultures lack the capability for such high yields. The table below highlights these differences:

| Culture Method | Peak Cell Density (cells/mL) | Antibody Production (g) | Viability After 14 Days | Nutrient Supply Method | Complexity Level |

|---|---|---|---|---|---|

| Batch | 2 × 10^7 | N/A | ~100% | Initial base medium | Low |

| Fed-Batch | N/A | 5-fold increase | N/A | Nutrients added as needed | Medium |

| ATF Perfusion | 7.4 × 10^7 | 11.4 | ~100% | Continuous supply | High |

Advantages of Continuous Operation

Continuous operation in hollow fiber perfusion systems offers significant advantages over traditional methods. These systems maintain uninterrupted nutrient delivery and waste removal, creating an optimal environment for cell growth and proliferation. This approach eliminates the need for external intervention, reducing downtime and improving scalability.

Key benefits include increased cell density, enhanced productivity, and reduced medium consumption. For example, hollow fiber bioreactors can amplify T cell yields from 10.8 billion to over 28 billion in just 10 days. Improved gas exchange and metabolite management further contribute to the efficiency of continuous operation.

- Continuous manufacturing is increasingly adopted in the biopharmaceutical industry.

- Automated processes ensure consistent production and minimize human error.

- Scalability becomes more accessible, supporting both research and industrial applications.

Cost Efficiency and Resource Utilization

Hollow fiber perfusion systems excel in cost efficiency and resource utilization. By reducing medium consumption and enabling higher cell densities, these systems lower operational costs while maximizing output. Traditional batch methods often require frequent media replacement, increasing expenses and labor.

Continuous perfusion minimizes waste and optimizes resource use. For instance, hollow fiber system consumes up to 70% less medium compared to batch cultures. This reduction in resource usage not only cuts costs but also aligns with sustainable biomanufacturing practices. Enhanced scalability further supports cost efficiency, allowing researchers to expand production without significant increases in overhead.

The ability to achieve high productivity with minimal resource input makes hollow fiber perfusion a preferred choice in modern bioprocessing. Its advantages in cost and resource management underscore its transformative impact on the industry.

Impact of Hollow Fiber Perfusion on Biomanufacturing

Scalability for Large-Scale Biopharmaceutical Production

Hollow fiber perfusion systems offer unmatched scalability, making them ideal for large-scale biopharmaceutical manufacturing. These systems support high-density cell culture, enabling the production of significant quantities of therapeutic products within a compact footprint. Unlike traditional stirred tank systems, hollow fiber bioreactors (HFBRs) require 10 to 100 times less operating space while achieving higher cell densities. This efficiency reduces the need for extensive infrastructure, making them a practical choice for the biopharmaceutical industry.

The table below highlights the scalability benefits of hollow fiber perfusion compared to traditional systems:

| Feature | Hollow Fiber Bioreactors (HFBRs) | Traditional Systems (e.g., Stirred Tank) |

|---|---|---|

| Operating Footprint Reduction | 10 to 100 times smaller | Larger footprint |

| Product Harvest Volume Reduction | 10 to 100 times less | Higher volume required |

| Cell Density | High | Lower |

| Media Requirements | Simplified, less expensive | More complex, expensive |

| Adaptation Requirement | None (attached cultures) | Lengthy adaptation needed |

| Downstream Processing Efficiency | Facilitated by lower impurities | More complex due to higher impurities |

| Continuous Production Capability | Yes | Limited |

This scalability ensures that hollow fiber perfusion systems can meet the growing demands of the pharmaceutical industry while maintaining efficiency and cost-effectiveness.

Reducing Costs in Bioprocessing

Hollow fiber perfusion significantly reduces operational costs in bioprocessing. These systems consume less media and require fewer seed train materials, leading to substantial savings. For example, the cost per gram of antibody produced using hollow fiber systems is less than $65, compared to over $300 in traditional systems. Simplified media requirements further reduce expenses, as hollow fiber systems eliminate the need for costly growth factors.

The table below illustrates the cost advantages of hollow fiber perfusion:

| Cost Aspect | Traditional System Cost | Hollow Fiber Cost | Savings |

|---|---|---|---|

| Cost per gram of antibody | $300 or more | Less than $65 | Significant reduction |

| Media costs | Higher due to growth factors | Lower due to simple media | Overall reduction in media costs |

| Seed train materials and labor | Higher due to scale-up | Lower inoculum requirement | Significant savings in materials and labor |

By reducing capital investment and operating costs, hollow fiber perfusion aligns with sustainable biopharmaceutical manufacturing practices. These savings make advanced therapies more accessible to patients worldwide.

Enabling Innovation in Biopharmaceutical Development

Hollow fiber perfusion drives innovation in the biopharmaceutical industry by enabling high-density cell cultures and continuous processing. These capabilities are essential for developing advanced therapies, including monoclonal antibodies and gene therapies. The ability to maintain continuous production accelerates research timelines and enhances product quality.

For instance, Cellular Agriculture Ltd is leveraging hollow fiber bioreactors to scale up cultivated meat production, showcasing their versatility beyond traditional biopharmaceutical processes. Additionally, the technology facilitates the development of novel therapies by providing a controlled environment for cell growth and differentiation. This adaptability supports the rapid evolution of the biopharmaceutical process, ensuring that researchers can meet the industry’s dynamic needs.

Hollow fiber perfusion also improves downstream processing efficiency by reducing impurities in harvested products. This feature simplifies purification steps, saving time and resources. By fostering innovation and improving efficiency, hollow fiber perfusion plays a pivotal role in advancing the biopharmaceutical industry.

Conclusion

Hollow fiber perfusion has transformed bioprocessing with its efficiency and versatility. It supports high-density cell culture, enabling continuous production and harvest across multiple applications.

- High cell retention efficiency reduces clogging, ensuring smoother operations.

- Monoclonal antibody production benefits from scalable yields and consistent quality.

- Recombinant protein production achieves higher concentrations with minimal resource use.

- Stem cell culture thrives in controlled environments that mimic in vivo conditions.

By driving scalability and cost reduction, hollow fiber perfusion fosters innovation and accessibility in biomanufacturing, making it indispensable for advancing therapeutic development.