Hydrophilic ptfe membrane plays a vital role in medical devices by enabling sterile filtration, controlled drug delivery, and precise sample handling. Clinicians rely on these membranes in blood filters, catheters, and other devices to protect patients and ensure following safety standards. The global market for hydrophilic ptfe membrane reached $1.2 billion in 2023, driven by medical applications that prioritize patient safety and device reliability.

- Blood filters

- Catheters

- Infusion sets

| Key Feature | Benefit in Medical Devices |

|---|---|

| Chemical resistance | Withstands harsh sterilization, maintains structure |

| Hydrophilicity | Supports fast, effective filtration of aqueous solutions |

| Low protein binding | Reduces risk of sample loss or contamination |

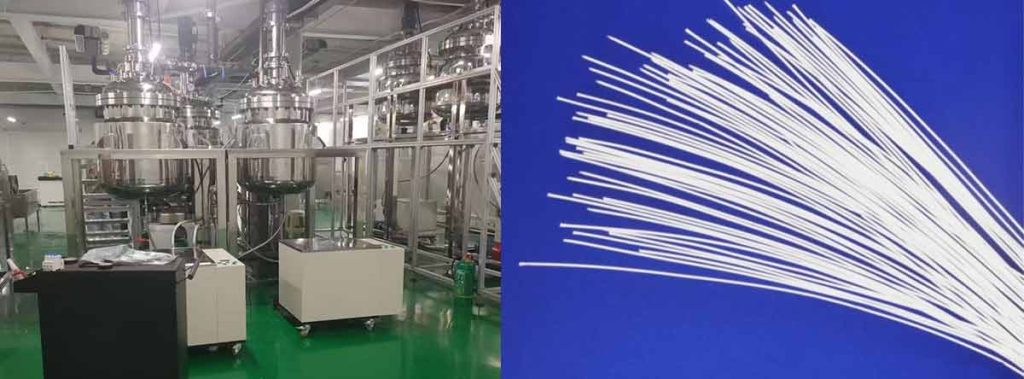

Hydrophilic ptfe membrane resists strong acids and high temperatures, making it ideal for use in medical environments where hollow fiber spinning machine ensures uniform pore size. These properties help devices meet strict safety requirements and protect patients during treatment.

Key Takeaways

- Hydrophilic PTFE membrane improves safety and reliability in medical devices by enabling effective filtration and controlled drug delivery.

- The membrane resists chemicals and heat, making them ideal for sterilization and long-term use in devices like blood filters, catheters, and infusion sets.

- The membrane helps remove impurities and air bubbles, ensuring clean samples and safe drug administration in diagnostic and infusion devices.

- Advanced manufacturing techniques, such as hollow fiber spinning, produce membranes with consistent pore sizes for reliable performance.

- Hydrophilic PTFE membrane supports patient comfort and device durability in applications like respiratory therapy, ostomy bags, and implantable drug delivery systems.

Filtration in Medical Devices

Infusion and IV Filters

Hydrophilic membrane filters play a crucial role in infusion and IV filters. These filters remove air bubbles from intravenous solutions, which helps prevent air embolism in patients. Syringe filters with hydrophilic ptfe membrane trap undissolved drug particles, bacteria, and endotoxins. This process reduces the risk of phlebitis and sepsis during intravenous therapy. Medical devices such as IV bags and catheters rely on these filters to maintain sterility and ensure safe drug delivery. Manufacturers use hollow fiber spinning machine to produce filters with consistent pore size, which supports reliable performance. Hydrophilic ptfe membrane in filter undergos ultrasonic welding and strict inspections. These steps guarantee leak-proof, single-use filters that protect patients from contamination. Syringe filters also act as venting membranes, allowing gases to escape while blocking fluids and contaminants. This design further enhances patient safety during pharmaceutical administration.

Tip: Always check that syringe filters are intact before use to ensure maximum protection for patients.

Biological Sample Filtration

Hydrophilic membrane filters are essential for filtering biological samples such as sputum, spinal fluid, and urine. Syringe filters with hydrophilic ptfe membranes maintain sample purity by removing particles and microorganisms. These filters support accurate diagnostic results by preventing contamination. Medical laboratories use syringe filters to prepare samples for analysis, ensuring that only clean fluids reach testing equipment. The hydrophilic membrane filter offers low protein binding and high chemical compatibility, which preserves the integrity of sensitive samples. Studies show that surface modifications, such as N2 plasma treatment, improve the hydrophilicity of ptfe membranes. This change enhances wettability and filtration efficiency, which is vital for medical applications. Syringe filters comply with strict safety standards, making them a trusted choice in clinical settings. Hydrophilic membrane filters also play a role in water treatment within healthcare, removing impurities and protecting both devices and patients.

- Syringe filters maintain cleanliness and purity in medicine production.

- Hydrophilic membrane filters remove disease-causing microorganisms, ensuring product efficacy.

- These filters support safe and effective delivery of pharmaceutical products.

Sterile Venting Applications

Hydrophilic membrane filters play a critical role in sterile venting for many medical devices. These filters allow air and gases to pass through while blocking fluids and contaminants. This function protects patients and maintains device safety. The microporous structure of hydrophilic ptfe membrane enables gas exchange without letting liquids enter sensitive equipment. Manufacturers often use a hollow fiber spinning machine to produce filters with precise pore sizes, ensuring consistent performance.

Respiratory Therapy Devices

Respiratory therapy devices, such as ventilators and oxygen concentrators, rely on hydrophilic membrane filters to maintain a sterile airflow. These filters prevent fluid ingress, which could otherwise compromise device function or introduce pathogens to patients. The hydrophobic surface of PTFE membranes repels water and other liquids, keeping internal components dry. This design supports reliable operation during repeated sterilization cycles. Medical staff trust these filters to protect patients with compromised respiratory systems.

- Ventilators use hydrophilic membrane filters to block fluids while allowing air to pass.

- Oxygen concentrators depend on these filters for sterile gas delivery.

Note: Hydrophilic membrane filters maintain sterility even after exposure to high-pressure steam and harsh chemicals.

Endoscopes and IVF Devices

Endoscopes and IVF devices require sterile venting to prevent contamination during procedures. Hydrophilic membrane filters in these devices allow gases to escape while blocking bodily fluids. This feature reduces the risk of infection and ensures accurate diagnostic results. The chemical resistance and thermal stability of hydrophilic ptfe membranes make them suitable for repeated sterilization. Case studies show that these filters outperform traditional materials in maintaining device integrity.

Ostomy Bag Venting

Ostomy bags use hydrophilic membrane filters to manage gas buildup and prevent leaks. The filters enable gas to vent safely without letting liquid escape. This function improves comfort and hygiene for patients. The mechanical durability of hydrophilic membrane filters ensures long-lasting performance, even under daily use. Patients benefit from reduced odor and a lower risk of skin irritation.

- Hydrophilic membrane filters in ostomy bags support patient dignity and safety.

- The filters’ design helps maintain a clean and comfortable experience.

Diagnostic and Analytical Devices

Diagnostic Assays

Diagnostic assays require high standards for accuracy and reliability. Medical professionals use syringe filters with hydrophilic ptfe membrane to prepare samples for analysis. These filters remove unwanted particles and microorganisms from blood, urine, and other fluids. The hydrophilic ptfe membrane allows fast filtration of aqueous solutions, which supports efficient laboratory workflows. Syringe filters also help maintain the safety and purity of medicines by preventing contamination during sample preparation.

Laboratories often choose syringe filters because they offer low analyte binding. This feature ensures that test results reflect the true composition of the sample. The filters work well with both aqueous and organic solutions, making them suitable for a wide range of diagnostic tests. The hollow fiber spinning machine produces filters with consistent pore size, which improves the reliability of diagnostic devices. Medical staff trust these filters to protect patients by delivering accurate results.

Tip: Using syringe filters in diagnostic assays reduces the risk of false positives or negatives, which helps doctors make better decisions for patients.

Sample Purity and Accuracy

Sample purity is essential for precise diagnostic and analytical work. Syringe filters play a key role in removing impurities from samples before testing. These filters prevent particles and bacteria from entering sensitive equipment, which helps maintain the purity of the sample. The hydrophilic ptfe membrane in syringe filters resists chemical attack and does not bind proteins or analytes. This property preserves the integrity of pharmaceutical samples and supports the safety and purity of medicines.

Syringe filters also support the accuracy of test results. By providing a clean sample, these filters help laboratories avoid errors that could affect patient care. The filters’ compatibility with a variety of solutions makes them a reliable choice for pharmaceutical and clinical laboratories. Patients benefit from improved diagnostic accuracy and safer treatments.

| Benefit | Impact on Diagnostic Devices |

|---|---|

| Low analyte binding | Accurate test results |

| Chemical resistance | Reliable performance with harsh reagents |

| Consistent pore size | Uniform sample filtration |

Drug Delivery and Implantable Devices

Controlled Release Systems

Hydrophilic PTFE membrane plays a vital role in controlled drug release systems within medical devices. The membrane enables precise delivery of medicines directly to targeted tissues. For example, a biodegradable wireless implantable device uses a hydrophilic drug-filled film as part of a bioabsorbable electronic patch. This patch, activated by a radio-frequency magnetic field, heats up and accelerates drug diffusion. In studies with canine brain tumor models, this approach delivered medicines safely to residual tumor cells, improving treatment outcomes.

Researchers have also combined hydrophilic PTFE membrane with acetylated polysaccharide layers to create a matrix for the anticancer drug gemcitabine. The acetylation process improves film formation and drug loading, allowing for sustained release over 30 days. In preclinical tests with colon tumor-bearing mice, these membranes enabled total tumor regression without systemic toxicity. The thickness and drug capacity of the membrane can be adjusted, which influences how quickly the medicine is released. Covered drug-eluting stents using this technology show promise for keeping medicines safe and improving chemotherapy in gastrointestinal cancer.

Note: The hollow fiber spinning machine helps produce membranes with consistent pore size, which is essential for reliable drug release.

Biocompatibility and Durability

Medical devices that remain inside the body require materials that are both biocompatible and durable. Hydrophilic PTFE membrane meets these needs. In rabbit models, implants made from PTFE-based membranes showed only mild and typical foreign body reactions after 30 days. Most inflammation resulted from surgery, not the material itself. The membrane has a stable porous structure, allowing fluid to circulate and preventing blockages.

The hydrophobic surface of the membrane resists protein adhesion, which helps maintain function over time. In vitro studies confirm that these membranes remain chemically stable and inert under simulated body conditions. Tests on mouse fibroblast cells show no cytotoxicity. The membrane also withstands long-term static and dynamic loading, making it suitable for implantable medical applications. Their resistance to harsh sterilization and bodily fluids ensures they continue delivering medicines safely throughout their use.

Manufacturing and Performance

Hollow Fiber Spinning Machine

Manufacturers use advanced techniques to produce hydrophilic PTFE membrane for medical devices. The hollow fiber spinning machine plays a central role in this process. Engineers often combine emulsion electrospinning with sintering to address the challenges of PTFE’s high melt viscosity and solvent resistance. In this method, a water-based emulsion containing PTFE particles and a small amount of water-soluble polymer forms composite fibers. Sintering at optimized temperatures removes the polymer and fuses the PTFE particles into pure nanofibers. This process creates hollow fiber membranes with a tubular structure and high porosity, often exceeding 82%. The resulting membranes show excellent mechanical strength and superhydrophobicity, which are essential for demanding medical applications.

Recent developments in hollow fiber membrane fabrication focus on green and sustainable methods. Continuous electrospinning produces nanofiber-covered hollow fiber membranes with high packing density and self-supporting features. These environmentally friendly techniques reduce pollution and equipment costs while improving membrane performance. The hollow fiber spinning machine enables scalable and cost-effective production, supporting the growing demand for reliable membranes in cleaning medical devices and other healthcare uses.

Consistent Pore Size

Consistent pore size in hydrophilic PTFE membrane ensures reliable filtration and fluid control in medical devices. Manufacturing quality directly impacts device safety and performance. High porosity and uniform pore distribution improve filtration efficiency and durability. Quality control measures guarantee high purity, low extractables, and chemical resistance. These attributes help maintain product integrity in critical applications such as venting filters, infusion filters, and diagnostic assays.

Manufacturers must meet strict regulatory standards set by agencies like the FDA and EU. They conduct extensive testing, including accelerated aging and resistance to sterilization, to verify membrane durability. Collaboration with surface-treatment experts during design helps address challenges like coating flaking or shedding. Regulatory agencies require that coatings maintain safety and performance throughout the device’s lifecycle. Ongoing innovation in coating materials and manufacturing methods ensures that hydrophilic PTFE membrane continues to meet evolving expectations for medical device safety and reliability.

Tip: Consistent manufacturing quality supports the safety and effectiveness of medical devices used in patient care.

Conclusion

Hydrophilic PTFE membrane supports a wide range of medical applications, from filtration to drug delivery. Their high filtration efficiency, chemical stability, and long service life help ensure safety and reliability in medical devices. Manufacturers use advanced methods like the hollow fiber spinning machine to achieve precise pore sizes and consistent performance. Recent innovations improve hydrophilicity and compatibility with sterilization, making these membranes essential for modern healthcare. As technology advances, these membranes will continue to drive innovation in medical device design.