Hollow fiber filters simplify blood plasma separation by offering a practical alternative to centrifugation. Hospitals and laboratories use hollow fiber filters to achieve efficient plasma separation with fewer steps and reduced risk of contamination. Hollow fiber spinning machine helps produce consistent filters that maintain high quality. Researchers apply several statistical tests, shown below, to compare the effectiveness of plasma separation techniques:

| Statistical Test | Purpose |

|---|---|

| Unpaired t-test | Compare differences between blood products based on separation method |

| Mann-Whitney U test | Compare differences when normality is not assumed |

| Two-way repeated measures ANOVA | Assess impact of separation method and sample origin on blood product quality |

| Fisher’s exact test | Evaluate differences in proportions meeting quality criteria |

Clinical studies highlight key safety benefits of hollow fiber filters:

- Lower adverse reaction rates due to albumin supplementation

- Selective removal of plasma components, reducing complications

- Faster processing times and improved patient safety

Hollow fiber filters support reliable plasma separation and promote safety in medical settings.

Key Takeaways

- Hollow fiber filters streamline plasma separation, making the process faster and safer for patients.

- These filters reduce contamination risks and preserve blood cell integrity, leading to better clinical outcomes.

- Using hollow fiber filters simplifies workflows in hospitals and laboratories, enhancing efficiency in plasma processing.

- Hollow fiber technology offers a reliable alternative to traditional centrifugation, lowering operational costs and improving patient care.

- Clinical staff should consider hollow fiber filters for their ability to maintain high-quality plasma while minimizing complications.

Hollow Fiber Filters and Their Structure

What Are Hollow Fiber Filters?

Hollow fiber filters play a key role in membrane separation technique applications, especially in medical and laboratory settings. These filters consist of many hollow fiber membrane straws bundled together, each resembling a thin tube. The walls of these straws contain tiny pores that allow selective passage of fluids and particles. The pore size determines what substances can pass through. For example, a pore size of 0.2 microns removes bacteria and protozoa, while a 0.02-micron pore size can filter out viruses. This structure increases the surface area available for filtration, making the filters highly efficient even in compact devices.

The design of hollow fiber membranes supports both membrane plasma separation and other membrane separation technique processes. Plasma separation membranes rely on these precise pore sizes to separate plasma from blood cells without damaging sensitive components. The efficiency of membrane plasma separation depends on the ability of the filter to maintain high flow rates and retain important molecules like albumin and immunoglobulins. Studies show that a pore size of 0.55 microns can achieve high plasma flow rates and excellent retention of large molecules, which is crucial for clinical applications.

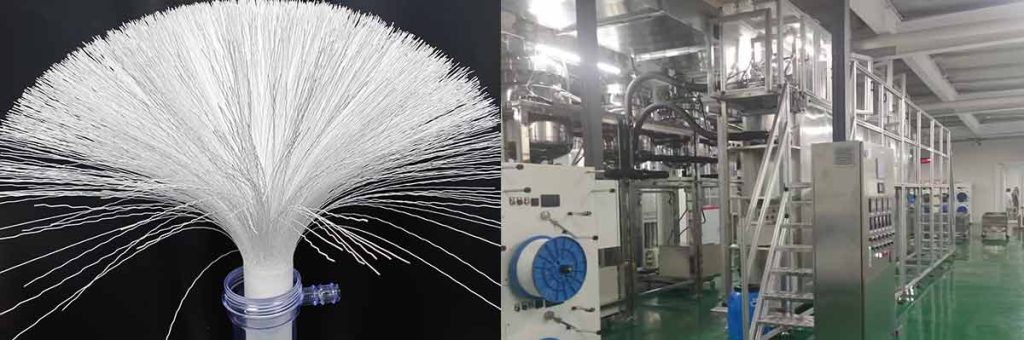

How Hollow Fiber Spinning Machines Shape Filter Quality

A hollow fiber spinning machine determines the consistency and performance of hollow fiber filters. These machines use advanced controls to monitor and adjust production parameters such as flow rate, temperature, and pressure. This real-time adjustment ensures that each fiber has uniform dimensions and pore structure.

Industrial hollow fiber spinning equipment can provide the degree of control required for quality membrane production even at a high rate. This implies membranes made in the laboratory can be scaled up with little loss in performance.

Manufacturers use several quality control measures during the hollow fiber spinning:

| Quality Control Measure | Description |

|---|---|

| Routine Inspections | Identify cracks or leaks that can affect filter performance. |

| Integrity Testing | Detect potential failures early by evaluating membrane function. |

| Chemical Compatibility Checks | Ensure cleaning solutions do not damage the membrane. |

| Maintenance Practices | Track trends and optimize system performance with regular checks. |

| Pre-treatment of Feedwater | Remove impurities before filtration to reduce fouling risks. |

The hollow fiber membrane spinning machine also allows for adjustments in spinning parameters, which can change the pore size and structure of the fibers. This flexibility supports the development of membrane separation technique solutions tailored for specific clinical needs. By maintaining strict quality standards, manufacturers produce plasma separation membranes that deliver reliable and safe results in medical environments.

Plasma Separation Process with Hollow Fiber Cartridge

Filtration Steps in Plasma Separation

A hollow fiber cartridge enables efficient plasma separation by guiding blood through a series of controlled steps. The process begins when whole blood enters the system and flows into the hollow fiber cartridge. The cartridge contains thousands of thin, porous fibers that act as selective barriers. Plasma moves through the fiber walls, while blood cells and larger particles remain outside the fibers.

Researchers have tested the system at different filtrate flow rates in cross flow mode. Both the retentate and permeate recirculate in the reservoir, which helps maintain consistent plasma quality. The affinity membrane inside the hollow fiber cartridge can fractionate plasma proteins at fast flow rates. Residence times below ten seconds allow the system to trap proteins efficiently. When residence times drop below five seconds, protein trapping increases. The dynamic maximum capacity reaches 190 μg/cm², while equilibrium capacity is 148 μg/cm². The system demonstrates high selectivity for immunoglobulin G (IgG) from diluted plasma samples. Dissociation constants for IgG are 3.7 × 10−6 M in dynamic mode and 9.8 × 10−6 M in equilibrium binding analysis.

The following ordered list outlines the main steps in plasma separation using a hollow fiber cartridge system:

- Whole blood enters the system and flows into the hollow fiber cartridge.

- Blood circulates around the outside of the fibers, while plasma passes through the fiber walls.

- The system recirculates both retentate and permeate to maintain plasma quality.

- The affinity membrane fractionates plasma proteins at fast flow rates.

- The system traps proteins efficiently with short residence times.

- The cartridge selectively isolates plasma components, such as IgG, from diluted samples.

- The system collects separated plasma for further analysis or clinical use.

Note: Fast flow rates and short residence times improve protein trapping and plasma fractionation in the hollow fiber cartridge system.

Outside-In Filtration and Gravity Techniques

Outside-in filtration plays a crucial role in plasma separation within hollow fiber cartridge. In this method, blood flows through the inter-fiber space, while the dialysate or buffer moves inside the fiber lumens. This configuration reduces the risk of fiber clogging, which often occurs in conventional inside-out filtration systems. The smooth, hydrophilic outer layer of the membrane enhances plasma filtration and toxin removal. The system maintains high flow rates and extends treatment duration, which benefits both patients and clinicians.

Several factors contribute to the effectiveness of outside-in filtration in hollow fiber cartridge systems:

- A larger membrane area lowers transmembrane pressure, reducing clogging occurrences.

- The CH-1.8W filter, with a larger membrane area, operates longer before clogging compared to smaller filters.

- The differential pressure between the inside and outside of the fiber facilitates plasma filtration and removes particulate matter.

- Flow rates of about 2.0 ml/min are achieved with a pressure difference of around 1 bar, supporting efficient plasma separation.

- The system can process more than 4 liters of plasma containing high solids content before clogging occurs, maintaining consistent flow rates.

Gravity-based separation offers another approach for plasma isolation in hollow fiber cartridge. This technique relies on gravity to move plasma through the cartridge, which simplifies the process and reduces mechanical stress on blood cells. The following table compares the efficiency of gravity-based separation systems:

| System | Processing Time | RBC Unit Volume | Platelet Recovery | Clotting Factor Concentration |

|---|---|---|---|---|

| 3M Blood Separation System | 64 minutes | 293 mL | Lost | Significantly diminished |

| ErySep Classic Blood Separation System | 140 minutes | 306 mL | Lost | Significantly diminished |

Gravity-based systems process plasma at different rates and affect the recovery of blood components. The 3M Blood Separation System completes processing in 64 minutes, while the ErySep Classic Blood Separation System takes 140 minutes. Both systems show diminished clotting factor concentration and loss of platelets, which highlights the importance of optimizing plasma separation techniques.

Plasma separation using hollow fiber cartridge combines advanced filtration methods and gravity techniques to deliver efficient, safe, and reliable results. The system preserves plasma quality, reduces clogging, and maintains high flow rates, making it a valuable tool in clinical and laboratory settings.

Benefits of Hollow Fiber Filters in Plasma Systems

Efficiency and Cell Preservation

Hollow fiber filters deliver remarkable efficiency in plasma separation. Medical staff rely on these filters to process plasma quickly, which supports high-throughput environments. The design of hollow fiber dialysis modules increases blood flow rates and enhances treatment efficacy. Membrane technologies allow selective separation of plasma components, which eliminates the need for substitution solutions and streamlines the workflow.

Researchers have measured the ability of hollow fiber filters to preserve blood cell integrity during plasma separation. The following table presents quantitative data on filtration rate, cell viability, and enucleate purity for different filtration types and platforms:

| Platform | Filtration Type | Filtration Rate (cells/h) | Cell Viability (%) | Enucleate Purity (%) |

|---|---|---|---|---|

| Water | Cross-filtration | 7 × 10⁵ | 88 | 92 |

| DMSO | Cross-filtration | 44 × 10⁵ | 89 | 81 |

| Water | Dead-end filtration | 1.6 × 10⁸ | 96 | 84 |

| DMSO | Dead-end filtration | 1.8 × 10⁸ | 99 | 81 |

This data shows that hollow fiber filters maintain high cell viability and enucleate purity. The process preserves sensitive blood cells, which is essential for clinical applications. The chart below illustrates the comparison of cell viability and enucleate purity for different filtration types and platforms:

Hollow fiber dialysis systems support membrane plasma separation with minimal cell damage. The technology ensures that white blood cells and platelets remain intact, which improves the quality of plasma for transfusion and drug development. The biocompatibility of the membrane materials further reduces the risk of adverse reactions. Medical staff observe no loss of corpuscular components, which increases the reliability of plasma separation.

Tip: Hollow fiber filters offer high biocompatibility, which helps maintain the integrity of blood cells and plasma proteins during separation.

Safety and Simplicity

Hollow fiber filters simplify the plasma separation process for medical staff. The technology replaces complex centrifuge systems with straightforward membrane techniques. Fully automated apheresis machines use hollow fiber modules, which eliminate the need for continuous manual control. This advancement reduces the complexity of procedures and improves efficiency in clinical settings.

Medical staff benefit from several key advantages when using hollow fiber filters for plasma separation:

- The process is faster, which reduces patient waiting times.

- The risk of contamination decreases, which improves safety.

- Membrane techniques are safer to apply than centrifuges, which lowers the chance of cell damage.

- The system allows complete separation of corpuscular components from plasma, which enhances efficacy.

- The introduction of hollow fiber modules increases blood flow rates and treatment efficacy.

Hollow fiber dialysis systems support selective separation of plasma components, which simplifies the workflow for clinicians. The use of membranes leads to no observed loss of white blood cells or platelets, which makes the process more efficient. The biocompatibility of the membrane materials ensures that plasma separation remains safe for both patients and medical staff.

Note: Membrane plasma separation with hollow fiber filters reduces the risk of contamination and cell damage, which supports safer and simpler clinical procedures.

Comparing Hollow Fiber Dialyzer and Traditional Methods

Centrifugation vs. Hollow Fiber Dialyzer

Centrifugation has served as the standard for plasma separation in clinical laboratories for decades. This method uses high-speed spinning to separate plasma from blood cells. The process requires significant energy and time, which increases operational costs. Hollow fiber dialyzer systems offer a modern alternative. These systems use membranes that allow plasma components to pass through while retaining cellular elements. The membrane-based approach can reduce operational costs because it streamlines the workflow and uses less energy.

Hollow fiber dialyzer supports single-pass tangential flow filtration. This advancement shifts plasma separation toward greater efficiency. Biomanufacturing facilities benefit from lower operational costs compared to traditional centrifugation. The workflow differences between centrifugation and hollow fiber dialyzer-based separation appear in the following table:

| Feature | Centrifugation | Hollow Fiber Dialyzer |

|---|---|---|

| Blood/Plasma Flow Ratio | 2:1 | ≥3:1 |

| Treatment Time | Shorter compared to filtration | Optimized for efficiency |

| Patient Suitability | Suitable for vascular conditions | Effective for toxin removal during hemodialysis |

| Preparation Time | 10–15 min | 15–20 min |

Centrifugation provides shorter treatment times, but hollow fiber dialyzer systems enhance solute transport and fluid balance. Both methods aim to optimize patient care and streamline clinical workflows.

Simplified Blood Processing

Hollow fiber dialyzer systems simplify blood processing by eliminating several steps required in traditional plasma separation. Medical staff no longer need to perform multiple centrifugation cycles. The membrane-based approach retains blood components while filtering out unwanted substances. The following list highlights process steps eliminated by hollow fiber dialyzer systems:

- Removal of up to 95% of DMSO from cryopreserved platelets, compared to only 52% with centrifugation.

- Elimination of repeated centrifugation steps, which streamlines plasma separation.

- Effective retention of blood components during filtration.

Hollow fiber dialyzer systems have been in use since the 1980s. Continuous improvements have made them a safe alternative for patients with drug-resistant diseases. The technology reduces the need for complex separation processes.

Blood processing turnaround times improve with hollow fiber dialyzer systems. The flushing method uses less washing solution and achieves higher protein recovery rates. The following table compares turnaround time impact:

| Method | Washing Solution Volume | Protein Recovery Rate | Turnaround Time Impact |

|---|---|---|---|

| Flushing | Reduced (350 mL less) | Improved | Faster processing |

| Traditional | Larger volumes | Lower recovery | Slower processing |

Hollow fiber dialyzer systems deliver efficient plasma separation, lower operational costs, and simplified workflows. These advantages make them a valuable choice for modern clinical and laboratory environments.

Clinical Applications of Hollow Fiber Filters

Plasmapheresis and Blood Banks

Hollow fiber bioreactor has transformed the plasma exchange procedure in clinical environments. Hospitals and blood banks use hollow fiber bioreactor systems to perform therapeutic plasma exchange with greater efficiency. These systems support separation of plasma from blood cells, which is essential for treating autoimmune disorders and managing blood-related diseases. Clinical research demonstrates that hollow fiber bioreactor filters enable rapid plasma exchange procedure cycles, reducing patient discomfort and improving outcomes.

Clinical studies compare different systems for plasma exchange procedure. The table below shows the performance of automated systems using hollow fiber bioreactor membranes and rotating cylinder technology:

| System Type | Plasma Collected (cc) | Time (min) | Filter Type |

|---|---|---|---|

| Automated System 1 | 500-600 | 30-50 | Hollow Fiber Membrane |

| Automated System 2 | 500-600 | 30-50 | Hollow Fiber Membrane |

| Automated System 3 | 500-600 | 30-50 | Rotating Cylinder (Couette Flow) |

Blood banks worldwide have adopted hollow fiber bioreactor filters for separation tasks. Increased funding for blood-research programs has accelerated the use of these technologies. Manufacturers now produce single-use plasma separation membranes, which supports safer and more efficient therapeutic plasma exchange. The disposable blood filters industry segments products by application and geography, helping clinicians select the best solution for each clinical research need. Global health agencies highlight the importance of technological breakthroughs in managing blood disorders. Automation and IoT systems in blood processing have modernized blood banks, making hollow fiber bioreactor filters a preferred choice.

Versatility in Medical Settings

Hollow fiber bioreactor filters offer versatility across a wide range of clinical settings. Hospitals use these filters for therapeutic plasma exchange, drug development, and separation of plasma proteins. Researchers rely on hollow fiber bioreactor systems to support clinical research and improve separation efficiency. The technology adapts to different workflows, making it suitable for emergency rooms, outpatient clinics, and specialized laboratories.

Clinicians value the ability of hollow fiber bioreactor filters to maintain cell integrity during separation. The filters reduce contamination risk and support high-throughput plasma exchange procedure cycles. Drug development teams use hollow fiber bioreactor systems to isolate plasma proteins for analysis. The filters also support separation in stem cell therapy and regenerative medicine. Hospitals benefit from the flexibility of hollow fiber bioreactor technology, which integrates with existing equipment and supports a variety of clinical research protocols.

Tip: Hollow fiber bioreactor filters provide reliable separation for therapeutic plasma exchange, drug development, and clinical research, making them essential tools in modern medicine.

Unordered list of adoption trends in blood banks:

- Commercial and regulatory dynamics influence the adoption of plasma separation membranes.

- Funding for blood-research programs increases the use of hollow fiber bioreactor filters.

- Manufacturers scale production for single-use membranes, supporting wider clinical adoption.

- The disposable blood filters industry segments products by type and geography.

- Emerging use cases across industries show growing acceptance in blood banks.

- Global health agencies emphasize technological breakthroughs for blood disorder management.

- Automation and IoT systems modernize blood banks, increasing the use of hollow fiber bioreactor filters.

Conclusion

- Hollow fiber filters increase the speed and safety of plasma separation.

- Medical teams observe fewer complications and better cell preservation.

- Hospitals and laboratories benefit from simplified workflows and reduced contamination risks.

Hollow fiber filters offer a reliable alternative to centrifugation. Clinical staff should consider these filters for efficient plasma separation and improved patient outcomes.

FAQ

What Is a Hollow Fiber Filter?

A hollow fiber filter uses thousands of tiny, straw-like fibers with porous walls. These fibers separate plasma from blood cells. Hospitals and labs use them for safe and efficient plasma separation.

How Does Plasma Separation with Hollow Fiber Filters Differ from Centrifugation?

Hollow fiber filters use membranes to separate plasma, while centrifugation relies on spinning blood at high speeds. The membrane method reduces contamination risk and preserves cell integrity.

Hollow fiber filters simplify the process and improve safety.

Are Hollow Fiber Filters Safe for Patients?

Medical teams observe fewer complications with hollow fiber filters. The biocompatible materials help protect blood cells and plasma proteins.

- Lower risk of cell damage

- Reduced contamination

Can Hollow Fiber Filters Be Used in Blood Banks?

Blood banks use hollow fiber filters for plasma separation and therapeutic plasma exchange. The technology supports high-throughput workflows and maintains plasma quality.

Hospitals and research centers rely on these filters for reliable results.

What Maintenance Do Hollow Fiber Filter Systems Require?

Routine inspections and integrity testing help maintain filter performance. Staff check for cracks, leaks, and membrane function.

| Maintenance Task | Purpose |

|---|---|

| Inspection | Detect physical flaws |

| Testing | Ensure proper function |