Thermal and chemical stability defines the performance and lifespan of hollow fiber membrane materials in demanding environments. Engineers select advanced polymers and ceramics to resist degradation. Ceramic membranes stand out for their durability, superior thermal stability, and strong resistance to harsh chemicals.

- PVDF-SiO2-HDTMS composite membranes deliver excellent long-term performance, maintaining a low reduction in CO2 mass transfer flux even after extended exposure to chemicals.

- In contrast, less stable membranes show significant performance drops over time.

| Evidence | Description |

|---|---|

| Additives | Improve mechanical strength, hydrophilicity, and operational robustness of membranes. |

| Complementary Strategies | Work alongside surface modification and structural optimization for enhanced durability and effectiveness. |

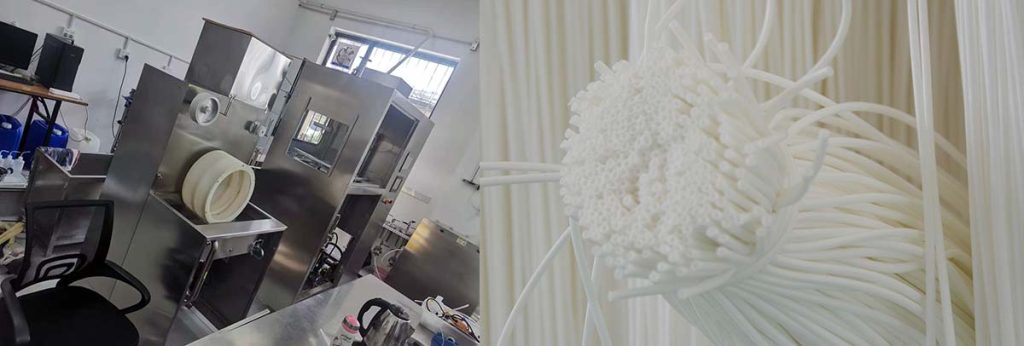

Process optimization, including the hollow fiber spinning machine, further strengthens membrane stability. A combined approach using material choice, surface treatments, and additives offers the best results.

Key Takeaways

- Selecting high-performance polymers like PES and TPAN enhances thermal stability and chemical resistance in hollow fiber membranes.

- Incorporating additives such as nanoparticles and stabilizers significantly improves the durability and lifespan of membranes in harsh environments.

- Optimizing the hollow fiber spinning is crucial for achieving desired membrane properties, ensuring better performance and stability.

- Surface treatments can tailor membrane characteristics, increasing hydrophobicity and mechanical strength for improved efficiency.

- Combining different materials and strategies leads to the most effective hollow fiber membranes, meeting the demands of modern industrial applications.

Stability Challenges

Thermal Degradation

Hollow fiber membranes often face significant thermal degradation during industrial processes. Many applications require high thermal stability to maintain performance under elevated temperatures. Some polymers, such as low density polyethylene, show morphological changes when exposed to heat and chemicals. Amine solutions can penetrate the pores of these membranes, causing both physical and chemical degradation. Auto-oxidation of the polymer further accelerates damage, especially in the presence of heat. Researchers have found that adding piperazine can help reduce these effects, but the challenge remains for many membrane types. Maintaining thermal stability ensures that hollow fiber membranes retain their structure and function over time.

Chemical Resistance

Chemical stability is essential for hollow fiber membranes used in harsh environments. Many industrial processes expose membranes to aggressive solvents and corrosive chemicals. Solvent resistance becomes a critical property, as some membranes degrade quickly when exposed to organic solvents. Swelling behavior often occurs, leading to dimensional changes that affect selectivity and can cause failure. Membranes with poor solvent resistance may lose their mechanical integrity, especially under operational pressures. Engineers must select materials with high chemical stability and solvent resistance to ensure long-term operation.

Performance Impact

Stability challenges directly impact the performance of hollow fiber membranes. Limited membrane availability for specific applications can slow technology adoption. Fouling remains a persistent issue, reducing membrane lifespan and efficiency. When membranes lack sufficient solvent resistance, they may swell or degrade, leading to loss of selectivity and mechanical strength. These problems can compromise the overall process, resulting in higher maintenance costs and reduced productivity. By addressing thermal stability, chemical stability, and solvent resistance, engineers can extend the service life and reliability of hollow fiber membranes in demanding industrial settings.

Material Selection for Hollow Fiber Membrane

High-Performance Polymers

High-performance polymers form the backbone of many hollow fiber membranes. These materials offer high thermal stability and excellent solvent resistance, making them suitable for demanding industrial applications. Engineers often select polymers such as polyethersulfone (PES), polysulfone (PSF), thermally rearranged polyarylnaphthalene (TPAN), and Matrimid for their unique properties.

- PES and PSF maintain their structure and function in harsh environments. PES can operate continuously at temperatures up to 200 °C, while PSF remains stable at similar conditions.

- TPAN stands out for its high thermal stability, withstanding temperatures up to 400 °C. This property makes it ideal for processes that require exposure to extreme heat.

- Matrimid offers even greater thermal stability, performing reliably at temperatures as high as 550 °C.

- The presence of aromatic groups in these polymers reduces chain flexibility, which increases both thermal stability and solvent resistance.

- High glass transition temperatures (Tg) indicate greater rigidity and stability. For example, PES has a Tg of 223 °C, and PSF has a Tg of 220 °C.

- Bulky side groups and high molecular weight further enhance the performance of these polymeric hollow fiber membranes, improving both gas permeability and aging resistance.

These structural features help polymeric hollow fiber membranes resist degradation from heat and chemicals. As a result, they deliver consistent performance and long service life in applications where both thermal stability and solvent resistance are critical.

Inorganic and Hybrid Materials

Inorganic and hybrid materials have become increasingly important for hollow fiber membranes. Ceramic membranes, for example, provide high durability and exceptional resistance to aggressive chemicals. These membranes excel in hostile environments, such as those involving strong acids or bases.

Hybrid membranes combine organic polymers with inorganic components. This combination enhances both chemical stability and long-term separation performance. The use of anionic crosslinking and in-situ biomineralization in hybrid membranes leads to improved hydrophilicity and greater resistance to chemical attack. These features make hybrid hollow-fiber membranes more reliable than traditional polymeric hollow-fiber membranes, especially in applications that demand both high thermal stability and solvent resistance.

Hybrid anion exchange hollow fiber membranes also maintain drug retention over extended periods. This property demonstrates their enhanced stability and makes them suitable for pharmaceutical and chemical processing industries.

Stability Comparison

Material choice directly affects the durability and suitability of hollow fiber membranes for specific applications. The following table compares the thermal stability of key high-performance polymers:

| Material | Tg (°C) |

|---|---|

| Polyethersulfone (PES) | 223 |

| Polysulfone (PSF) | 220 |

| TPAN | 400 |

| Matrimid | 550 |

The next table summarizes the durability and application suitability of different membrane types:

| Membrane Type | Durability | Suitability for Applications |

|---|---|---|

| Ceramic Membranes | High | Hostile environments, ultrafiltration, microfiltration |

| Polymeric Membranes | Moderate | High throughput, low-maintenance operations |

| Hollow Fiber Membranes | Moderate to High | Dense packing, requires pre-filtration |

Ceramic membranes offer the highest durability and excel in ultrafiltration and microfiltration. Polymeric hollow fiber membranes provide moderate durability but are favored for high-throughput and low-maintenance operations. Hybrid hollow fiber membranes bridge the gap, offering improved thermal stability and solvent resistance for applications that require both reliability and efficiency.

Selecting the right material ensures that hollow fiber membranes meet the demands of each industrial process. High-performance polymers, inorganic materials, and hybrids each bring unique advantages. By understanding these differences, engineers can design hollow fiber membranes that deliver optimal performance, long service life, and resistance to both heat and chemicals.

Modification of Hollow Fiber Membrane

Surface Treatments

Surface treatments play a vital role in improving the thermal stability and chemical stability of hollow fiber membranes. Engineers use several methods to modify membrane surfaces, each offering unique benefits for industrial applications. These treatments can increase hydrophobicity, enhance mechanical strength, and reduce pore wettability. The following table summarizes the most effective surface treatment methods and their effects on membrane stability:

| Surface Treatment Method | Effect on Membrane Stability |

|---|---|

| Thermal treatment | Enhanced hydrophobicity for brine treatment |

| Plasma treatment | Modification of membrane surfaces |

| Surface segregation | Improvement in membrane properties |

| Cross-linking and impregnation | Increased stability and mechanical strength |

| Layer-by-layer assemblies | Enhanced mass transport and stability |

| Thermal posttreatment | Improved membrane performance |

| Membrane coating | Reduced pore wettability and enhanced stability |

Plasma treatment and chemical functionalization stand out for their ability to precisely control membrane surface characteristics. These techniques improve capture efficiency and can be scaled up for industrial production using roll-to-roll processes. Layer-by-layer assembly allows engineers to tailor surface chemistry, which directly influences separation efficiency. Recent advancements in material science have led to membranes with higher flux, better selectivity, and improved antifouling properties. Surface modification methods now enable tailored membrane properties without compromising structural integrity.

Polymer Blending

Polymer blending offers another effective strategy to enhance the stability of hollow fiber membranes. By combining different polymers, engineers can create membranes with improved solvent resistance, thermal stability, and mechanical strength. For example, blending a high-performance polymer with a more flexible one can result in a membrane that resists swelling and maintains selectivity under harsh conditions. Composite formation, which involves adding inorganic fillers or nanoparticles, further boosts membrane durability and performance.

Blended membranes often show better resistance to aggressive solvents and high temperatures. This approach allows for fine-tuning of membrane properties to meet specific application needs. Engineers can adjust the ratio of polymers or the type of additives to achieve the desired balance between permeability, selectivity, and stability. Polymer blending also supports the development of membranes that perform well in challenging environments, such as those involving strong acids, bases, or organic solvents.

Spinning Process Optimization

The spinning process plays a crucial role in determining the final properties of hollow fiber membranes. Engineers use the hollow fiber membrane spinning machine to control parameters such as dope composition, extrusion rate, air gap, and coagulation bath conditions. Optimizing these parameters ensures that membranes achieve the desired structure, pore size, and mechanical strength.

| Study | Key Findings |

|---|---|

| Hollow fiber (HF) membrane fabrication | The optimization of spinning parameters is crucial for achieving desired membrane properties, which directly impacts the stability and performance of hollow-fiber membranes. |

| Optimizing the spinning parameter of titania nanotube-boron incorporated PVDF dual-layered hollow fiber membrane | The optimization of key spinning parameters is crucial to attain the desired membrane properties to suit its application. |

The hollow fiber spinning machine allows for precise control over the membrane formation process. Adjusting spinning parameters can improve solvent resistance, enhance thermal stability, and increase overall membrane durability. Engineers often experiment with different settings to produce membranes that meet the specific requirements of each application. Proper process optimization leads to membranes with consistent quality, high performance, and long service life.

Tip: Careful adjustment of spinning parameters on the hollow fiber spinning machine can significantly improve membrane stability and operational efficiency.

Additives for Stability

Nanoparticles

Researchers often add nanoparticles to hollow fiber membranes to improve both thermal stability and chemical resistance. These tiny particles help strengthen the membrane structure and prevent degradation in harsh environments. Commonly used nanoparticles include:

- Magnesium oxide (MgO)

- Zinc oxide (ZnO)

- Aluminum oxide (Al2O3)

- Silicon dioxide (SiO2)

- Titanium dioxide (TiO2)

- Carbon nanotubes (CNTs)

- Graphene oxide (GO)

- Activated carbon (AC)

- Metal-organic frameworks (MOFs)

Nanoparticles can increase the mechanical strength of hollow fiber membranes and help maintain high solvent resistance. They also improve the membrane’s ability to filter out unwanted substances while keeping its structure stable at high temperatures.

Stabilizers

Stabilizers play a key role in protecting hollow fiber membranes from thermal and chemical damage. These additives work by reducing the rate of degradation and extending the membrane’s service life. Many stabilizers act as antioxidants or UV blockers, which helps prevent the breakdown of polymer chains. Some stabilizers also improve the membrane’s resistance to acids, bases, and organic solvents. By using stabilizers, engineers can create membranes that perform well in demanding industrial settings.

Note: The right choice of stabilizer depends on the specific application and the type of polymer used in the membrane.

Combined Additives

Combining different additives often leads to even greater improvements in hollow fiber membranes. For example, adding small molecular weight substances such as LiCl, water, and EG to PVDF membranes produces a strong synergistic effect. LiCl removes surface defects and macrovoids, which increases salt rejection and mechanical stability. Water enlarges pore size, resulting in higher permeate flux. EG narrows the pore size distribution and boosts anti-wetting properties, which supports long-term stability. This combination allows engineers to design hollow fiber membranes with optimized features for direct contact membrane distillation.

The long-term effects of additive incorporation on mechanical properties have been studied extensively. The table below summarizes key findings:

| Study | Findings |

|---|---|

| Huang et al. (2012) | Addition of low clay content (less than 10%) improves several properties of neat polymers. |

| Ma et al. (2012) | PSf/MMT nano-clay nanocomposite membrane showed increased porosity and pure water flux with higher clay content. |

| Hwang et al. (2011) | Nano-clay incorporation resulted in higher mechanical strength in porous PVDF membranes compared to neat membranes. |

| Yeh et al. (2004) | Membranes with montmorillonite showed enhanced anticorrosion and mechanical strength compared to PSf membranes. |

| Hashemifard et al. (2011) | Surface modified montmorillonite fillers improved CO2 removal performance in polyetherimide mixed matrix membranes. |

Additives, whether used alone or in combination, help engineers create hollow fiber membranes with improved thermal stability, high solvent resistance, and long-lasting performance.

Testing Methods

Thermal Assessment

Thermal assessment helps researchers understand how hollow fiber membranes respond to heat. They often use techniques such as thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC). These tests measure weight loss and heat flow as the membrane heats up. Scientists look for changes in specific heat capacity and enthalpy. The results show how much energy the membrane absorbs or releases during temperature changes. This information helps them predict if the membrane will keep its structure during high-temperature operations.

| Thermodynamic Property | Importance |

|---|---|

| Specific Heat Capacity (Cp) | Indicates heat required to change temperature, essential for thermal stability understanding. |

| Enthalpy Changes (ΔH) | Reflects heat absorbed/released during phase transitions, crucial for determining thermal history. |

Thermal screening tests give early insights into the reactivity of hollow fiber membranes. These results guide researchers as they develop new materials and improve existing ones.

Chemical Testing

Chemical testing checks how hollow fiber membranes resist aggressive agents. Researchers use several reliable protocols:

- Ageing prior to exposure: Simulates long-term performance by subjecting membranes to heat-humidity cycles or UV exposure.

- Conditions of exposure: Includes chemical concentration, contact temperature, duration, pressure, and the presence of cracks.

- Type of exposure: Determines if the chemical agent contacts one side or all sides of the membrane.

They follow a step-by-step process:

- Evaluate how ultrafiltration membranes respond to various chemical agents under controlled conditions.

- Assess changes in physical integrity and separation performance after chemical exposure.

- Develop standardized testing methodologies to predict membrane performance in real-world applications.

These tests help engineers choose the best hollow fiber membranes for harsh environments.

Data Interpretation

Interpreting data from thermal and chemical stability tests guides material selection and modification. Preliminary results from thermal screening help researchers identify promising materials for further development. This data also supports proper design during scale-up stages.

| Key Aspect | Description |

|---|---|

| Kinetic Calculations | Based on limited experimental data, specific criteria are needed to select the best kinetic model. |

| Modified Kinetic Computations | Allows for consideration of multiple reaction stages using various kinetic models. |

| Application | Used for predicting thermal stability in energetic and biological materials with approximately 30 data points. |

Note: Careful interpretation of test results ensures that engineers select hollow fiber membranes with the right balance of thermal and chemical stability for each application.

Conclusion

Engineers improve the stability of hollow fiber membranes by combining advanced materials, surface treatments, and process optimization. The most effective strategies include:

- Applying fluoropolymer coatings such as PTFE or PVDF for chemical stability

- Optimizing pore structure and creating composite hollow fiber membranes with multiple layers

- Incorporating nanoparticles, silicones, and stabilizers to reinforce the membrane

- Blending polymers and using crosslinking agents like zirconium for enhanced durability

Recent advancements in hollow fiber membrane manufacturing, such as 3D-printed spinnerets and dual-layer spinning, allow for precise control and improved performance.

| Advancement | Description |

|---|---|

| Precision and Reproducibility | Advanced sensors and PLC control ensure accurate flow rates and fiber diameters. |

| Dual-layer Spinning Procedures | Enables membranes with multiple functional layers, improving selectivity and mechanical strength. |

Ongoing evaluation of hollow fiber membranes helps identify materials that last longer and reduce operational costs. Customers now value solutions with lifespans over three years. By integrating these approaches, engineers create hollow fiber membranes that meet the demands of modern industry.

FAQ

What Makes Hollow Fiber Membranes More Stable Than Flat Sheet Membranes?

Hollow fiber membranes have a unique structure that increases surface area and mechanical strength. This design helps them resist pressure and chemical attack better than flat sheet membranes. Many industries choose hollow fiber membranes for challenging environments.

How Do Additives Improve the Stability of Hollow Fiber Membranes?

Additives such as nanoparticles or stabilizers reinforce the membrane structure. They help hollow fiber membranes resist heat and chemicals. These additives also improve the membrane’s lifespan and performance in harsh industrial processes.

Can Hollow-Fiber Membranes Be Used for High-Temperature Applications?

Engineers use hollow fiber membranes made from high-performance polymers or ceramics for high-temperature processes. These materials allow the membrane to maintain its structure and function even when exposed to extreme heat.

What Testing Methods Assess the Stability of Hollow Fiber Membranes?

Researchers use thermal and chemical tests to evaluate hollow fiber membranes. Thermal tests measure how the membrane reacts to heat. Chemical tests check resistance to acids, bases, and solvents. These methods help engineers select the right membrane for each application.

How Does The Spinning Process Affect Hollow Fiber Membrane Performance?

The spinning process shapes the hollow fiber membrane and controls its pore size and strength. Careful adjustment of spinning parameters ensures the membrane meets stability and performance requirements for specific uses.