Rapid waste reduction in hollow fiber membrane spinning machine remains achievable with immediate action. Manufacturers see major benefits when they adopt sustainable practices and focus on sustainability. Recycling efforts and smart resource management increase efficiency and lower environmental impact. Quick changes in production methods help companies meet strict standards and protect resources for future generations.

Key Takeaways

- Implement process optimization techniques to quickly reduce waste in hollow fiber spinning machine.

- Adopt efficient material handling practices, such as recycling failed membranes, to promote sustainability and lower waste output.

- Invest in operator training to enhance skills in waste management and recycling, leading to improved membrane quality.

- Upgrade to advanced spinneret and module designs to optimize performance and minimize material waste.

- Utilize automation and inline recycling systems to streamline production and support circular manufacturing efforts.

Immediate Techniques

Process Optimization

Process optimization delivers rapid results for waste reduction in hollow fiber spinning machine. Manufacturers can implement several techniques to minimize waste and enhance sustainability. The following table summarizes the most effective methods:

| Technique | Description | Waste Reduction Impact |

|---|---|---|

| Solvent Recovery and Recycling | Systems capture and purify solvents used in membrane spinning | Reduces environmental impact and production costs |

| Advanced Quality Control Systems | Real-time monitoring and automated adjustments | Maintains fiber dimensional consistency and structural integrity |

| Dry-jet Wet Spinning | Achieves higher polymer utilization rates | 85-95% polymer utilization, reducing waste compared to conventional methods |

| Microfluidic Dope Solution Preparation | Newer methods for preparing dope solutions | Up to 30% reduction in polymer waste compared to traditional methods |

These approaches support sustainable membrane production by reducing off-spec output and maximizing resource efficiency. Real-time monitoring enables operators to adjust parameters instantly, preventing unnecessary waste. Solvent recovery and recycling systems contribute to a green manufacturing environment and lower costs. Dry-jet wet spinning and microfluidic dope solution preparation improve polymeric membrane fabrication, leading to higher circularity and less waste.

Material Handling

Efficient material handling plays a vital role in sustainable membrane manufacturing. Companies can adopt several practices to reduce waste and promote circular production:

- Recycling failed membranes helps decrease overall waste output.

- The development of recyclable membrane materials leads to lower waste generation and supports green initiatives.

- Rieter’s technology enables the production of high-quality yarns from recycled materials, closing the loop in textile and membrane production.

- Waste recycling and waste reutilization strategies ensure that valuable resources remain in use, supporting circular economy principles.

- Proper separation of raw materials and finished membranes prevents contamination and increases recycling rates.

These practices enhance sustainability and support water treatment and separation processes. By focusing on recycling and circular material flows, manufacturers can reduce their environmental footprint and improve waste management.

Tip: Companies should regularly review their material handling protocols to identify new recycling opportunities and improve separation efficiency.

Operator Training

Upskilling operators leads to immediate improvements in waste minimization for hollow fiber spinning machine. Effective training programs focus on sustainability, recycling, and efficient membrane production. Key methods include:

- Employee involvement drives successful lean manufacturing and waste management initiatives.

- Cross-functional teams brainstorm solutions to waste issues and promote circular thinking.

- Training boosts employee morale and job satisfaction, resulting in better waste management and recycling outcomes.

- Instruction on equipment usage and recycling opportunities enhances team capability in membrane separation and water treatment.

- Engaging employees in waste reduction efforts uncovers unique insights and fosters a green workplace culture.

- Providing resources and support empowers staff to participate in continuous improvement and sustainability initiatives.

Companies that invest in operator training see rapid gains in membrane quality, reduced waste, and improved sustainability. Collaboration and knowledge sharing help teams identify inefficiencies and implement circular solutions quickly.

Waste Reduction in Hollow Fiber Membrane Spinning Machine

Advanced Spinneret Design

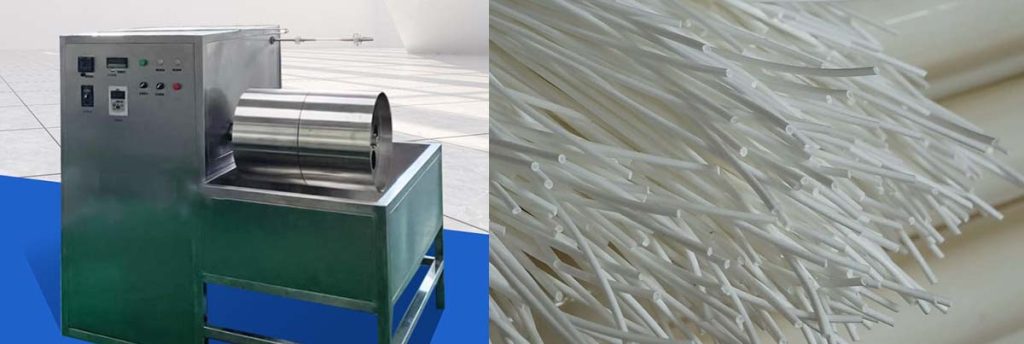

Innovations in spinneret design have transformed the hollow fiber membrane spinning machine. Engineers now use spinnerets that allow precise control over fiber dimensions. This control helps optimize membrane performance and reduces off-spec production. Adjustable spinneret geometry supports the creation of membranes with specific inner and outer diameters. These improvements lead to less material waste and better resource utilization.

Modern designs for hollow fiber spinneret also support sustainable manufacturing. Manufacturers select spinneret materials that resist corrosion and fouling, which extends equipment life. This approach reduces the need for frequent replacements and supports circular production. Companies that invest in advanced spinneret technology see immediate gains in membrane quality and waste reduction.

Note: Upgrading spinneret systems can help facilities achieve green manufacturing goals and improve recycling rates.

Module Design for Efficiency

Module design plays a critical role in sustainable membrane production. Engineers focus on features that boost productivity and minimize waste. The following table highlights key module design features and their contributions to efficiency and waste reduction:

| Design Feature | Contribution to Efficiency and Waste Reduction |

|---|---|

| High surface area per unit volume | Results in higher productivity compared to flat-sheet membranes. |

| Alterable fiber dimensions | Optimizes performance by adjusting inner and outer diameters. |

| Self-supporting structure | Facilitates backwashing and enhances fouling resistance. |

| High packing density | Increases durability and productivity of the membrane module. |

These features support circular manufacturing by maximizing membrane output and reducing raw material consumption. High packing density and self-supporting structures extend module life, which lowers waste generation. Alterable fiber dimensions allow operators to tailor membranes for specific water treatment and separation tasks.

Modular upgrades also impact the waste profile in hollow fiber membrane spinning machine. The table below shows how these upgrades contribute to sustainability:

| Environmental Impact | Reduction through Modular Upgrades |

|---|---|

| Energy Consumption | Up to 30% reduction |

| Water Usage | Significant reduction in cleaning cycles and production processes |

| Chemical Waste Generation | Reduced through bio-based materials and eco-friendly agents |

| Module Longevity | Extended by 40-60%, reducing waste generation over time |

Facilities that adopt modular upgrades experience lower energy and water usage. These changes support green initiatives and improve overall waste management. Extended module longevity means fewer replacements, which aligns with circular and sustainable production goals.

Phase Inversion Methods

Phase inversion methods have advanced membrane fabrication and waste minimization. Engineers use several techniques to produce high-quality membranes with less waste:

- Use of non-solvent additives, such as methanol or ethanol, in polyethersulfone solutions enhances water permeation and adjusts porous structures.

- Addition of polymer additives, including polyvinylpyrrolidone or polyethylene glycol, creates highly porous membranes from various polymers.

- Solution spinning and phase inversion techniques apply to hollow fiber membranes for high-temperature separation applications.

These methods support sustainable and circular manufacturing by improving membrane structure and reducing off-spec output. Facilities that use phase inversion techniques achieve better separation performance and lower waste recycling needs. The integration of polymeric membrane fabrication with advanced phase inversion supports green production and efficient water treatment.

Tip: Regular evaluation of phase inversion protocols can help companies identify new opportunities for waste reutilization and recycling.

Engineers and operators who focus on spinneret design, module efficiency, and phase inversion methods drive rapid waste reduction in hollow fiber spinning machine. These innovations support sustainability, circular production, and green manufacturing while improving membrane quality and separation efficiency.

Fast Technologies

Automation Systems

Automation systems deliver rapid improvements in sustainable membrane production. The Speedy Rotary Membrane System by SpinTek stands out in hollow fiber membrane spinning machine. This system uses a high shear Rotating Ceramic Ultrafilter, which extends bath life in metalworking and membrane fabrication. The ceramic membrane resists fouling and treats viscous waste streams efficiently. Operators need minimal assistance, and the compact design saves valuable floor space. These features support circular manufacturing and green initiatives by reducing manual intervention and optimizing separation processes.

- Speedy Rotary Membrane System by SpinTek

- High shear Rotating Ceramic Ultrafilter

- Ceramic membrane resists fouling

- Minimal operator assistance required

- Compact design saves space

Automation systems help facilities achieve sustainability goals quickly. They improve membrane quality, reduce waste, and support recycling efforts. Companies that invest in automation see measurable impacts on waste management and water treatment efficiency.

Inline Filtration & Recycling

Inline filtration and recycling technologies play a key role in sustainable membrane manufacturing. These systems filter waste streams during polymeric membrane fabrication, allowing immediate separation of reusable materials. Facilities can recycle failed membranes and off-spec products directly in the production line. This approach supports circular production and reduces the need for external waste management.

Operators monitor filtration units to ensure optimal recycling of waste. Inline systems help maintain membrane quality and minimize environmental impact. Water treatment processes benefit from cleaner effluent and reduced chemical usage. Inline recycling also supports green manufacturing by keeping valuable resources in use.

Tip: Regular maintenance of inline filtration units ensures consistent recycling performance and supports sustainability targets.

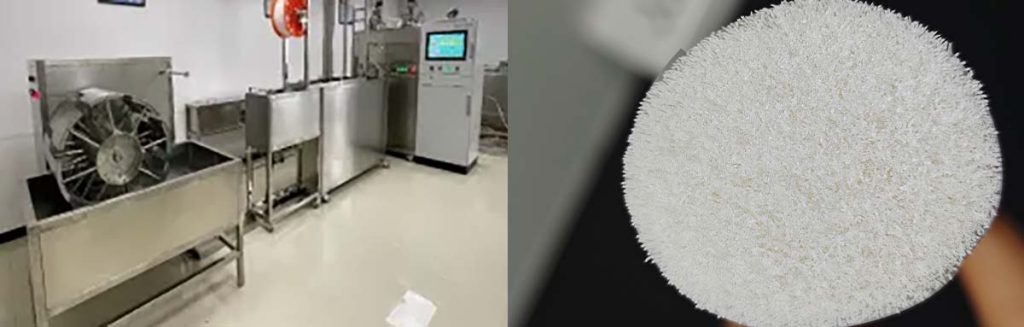

Waste Valorization Approaches

Waste valorization transforms discarded materials into valuable products for membrane and separation applications. Researchers have developed an improvised centrifugal spinning technique that produces polystyrene microfibers from waste expanded polystyrene foam. This method uses a modified benchtop centrifuge and achieves high yield with rapid production. Facilities can recycle polymeric waste into functional materials, supporting circular and sustainable manufacturing.

Waste materials such as polystyrene and expanded polystyrene are repurposed in membrane manufacturing. EPS waste dissolves in d-limonene and is spray coated on bacterial cellulose membranes, creating transparent BC-PS substrates. These BC-PS membranes perform well in OLED applications, showing fast impact in membrane technology and separation processes.

| Waste Material | Repurposing Method | Membrane Application | Impact |

|---|---|---|---|

| Polystyrene (PS), EPS | Centrifugal spinning, d-limonene dissolution | BC-PS substrates, OLED membranes | Rapid recycling, sustainable production |

Waste valorization supports recycling of waste, waste reutilization, and green manufacturing. Facilities that adopt these approaches improve sustainability and reduce their environmental footprint.

Quick Wins

Case Examples

Several companies have achieved fast results by applying sustainable strategies to their hollow fiber membrane spinning machine operations. One water treatment facility introduced inline recycling and reduced membrane waste by 40% within three months. The team used advanced separation techniques and focused on circular production. Another manufacturer adopted green waste reutilization methods, turning polymeric membrane fabrication scraps into new membrane modules. This approach improved recycling rates and supported a circular economy.

A third example comes from a membrane separation plant that invested in operator training. Employees learned sustainable practices and improved waste management. The plant saw a 25% drop in off-spec membrane production. These case studies show that sustainable and circular solutions can deliver quick wins for both the environment and business performance.

Companies that prioritize sustainability and recycling often see rapid improvements in membrane quality and waste reduction.

Timeframes & ROI

Facilities that implement sustainable changes in their hollow fiber membrane spinning machine often see results quickly. The table below shows typical timeframes and return on investment (ROI) for common strategies:

| Strategy | Timeframe to Results | Typical ROI (%) |

|---|---|---|

| Inline recycling | 1-3 months | 20-35 |

| Operator training | 2-4 months | 15-30 |

| Advanced separation technology | 3-6 months | 25-40 |

| Green waste reutilization | 2-5 months | 18-32 |

Sustainable membrane production not only reduces waste but also lowers costs. Circular approaches and recycling help companies recover valuable materials. Improved separation processes increase efficiency and support a green environment. Facilities that focus on sustainability and waste management often achieve positive ROI within the first half-year. These quick wins encourage further investment in sustainable and circular membrane manufacturing.

Conclusion

Manufacturers achieve rapid waste reduction in hollow fiber spinning machine by combining process optimization, advanced design, and automation. Integrating sustainability and recycling delivers long-term benefits:

- Reduces waste generation and conserves resources.

- Minimizes environmental impacts and supports Sustainable Development Goal 12.

- Mitigates greenhouse gas emissions and utility usage.

Key performance indicators help track progress:

| KPI | Description |

|---|---|

| Waste Generation & Composition | Measure total waste and categorize by type. |

| Diversion Rate | Percentage of waste diverted from landfills. |

| Contamination Rate | Rate of non-recyclables in recycling bins. |

| GHG Emissions | Emissions linked to waste transport and processing. |

| Financial Metrics | Disposal costs and revenue from recyclables. |

Ongoing monitoring and adaptation ensure continuous improvement for the environment.

FAQ

What Types of Waste Does a Hollow Fiber Spinning Machine Produce?

A hollow fiber spinning machine generates polymer scraps, solvent residues, off-spec membranes, and cleaning byproducts. Operators often recycle or treat these wastes to reduce environmental impact and improve sustainability.

How Can Operators Reduce Waste Quickly in Hollow Fiber Spinning Machine Operations?

Operators can adjust process parameters, use inline recycling systems, and improve material handling. Training staff and upgrading equipment also help achieve fast waste reduction.

Are Recycled Materials Safe for Use in Hollow Fiber Spinning Machine Production?

Yes. Many facilities use recycled polymers and solvents. Quality control systems ensure that recycled materials meet safety and performance standards for membrane production.

What Is the Typical ROI for Waste Reduction Investments in Hollow Fiber Spinning Machine Facilities?

Most facilities see a return on investment within three to six months. Savings come from lower disposal costs, reduced raw material use, and improved efficiency.

Can Automation Improve Sustainability in Hollow Fiber Spinning Machine Manufacturing?

Automation systems optimize production, reduce manual errors, and support real-time waste monitoring. These improvements help facilities achieve sustainability goals faster and with greater accuracy.