Polymer viscosity, especially dope viscosity, directly shapes hollow fiber spinning machine. Engineers observe that higher dope viscosity slows spinning speed, increases wall thickness, and boosts membrane selectivity. The melt spinning process depends on how dope viscosity controls fiber structure and phase inversion.

Researchers face challenges in dope viscosity control, balancing membrane morphology, defect suppression, and process scalability. The melt spinning process requires careful adjustment of dope composition and additives to optimize performance.

Key Takeaways

- Polymer viscosity controls how hollow fiber membranes form, affecting fiber thickness, structure, and performance.

- Maintaining dope solution viscosity between 10,000 and 60,000 mPa·s ensures stable spinning and high-quality fibers.

- Higher viscosity improves membrane selectivity but can slow production and make extrusion harder.

- Adjusting polymer concentration, molecular weight, temperature, and additives helps control viscosity for optimal results.

- Real-time monitoring of viscosity and spinning conditions prevents defects and keeps membrane quality consistent.

Polymer Viscosity and Hollow Fiber Spinning

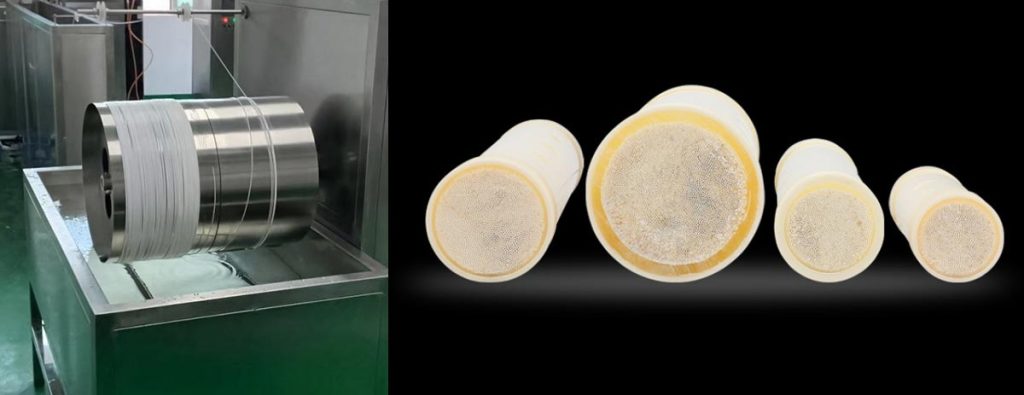

Role in Hollow Fiber Spinning

Polymer viscosity plays a central role in the hollow fiber spinning. The dope solution viscosity determines how the polymer flows through the hollow fiber spinneret and shapes the resulting fiber. Engineers observe that the viscosity of polymer solutions controls the morphology, geometry, and permeability of the hollow fiber membrane. The dope viscosity depends on polymer chain mobility and entanglement, which are influenced by molecular weight and additives like PEG. Changes in dope solution viscosity affect the phase inversion kinetics during spinning, which impacts how polymer chains pack in the membrane skin layer.

- The viscosity of spinning solutions influences:

- Flow rate through the hollow fiber spinneret

- Draw ratio and elongation of the fiber

- Spinning speed and residence time

- Molecular orientation and membrane structure

Higher dope solution viscosity leads to more controlled elongation and orientation of polymer chains. This results in improved membrane morphology and mechanical properties. The rheological behavior of the dope, including elongation viscosity, governs fiber formation dynamics under gravity and air gap conditions. Additives such as PEG can modify dope viscosity by changing polymer chain entanglement, which in turn affects phase inversion and membrane morphology.

Why Viscosity Matters?

Viscosity is a critical parameter in hollow fiber spinning machine. The viscosity effect influences the mutual diffusion rate between solvent and non-solvent, which determines membrane morphology and transport properties. Changes in dope solution viscosity alter spinning parameters such as flow rate, draw ratio, spinning speed, and residence time. These factors impact the final hollow fiber membrane structure and performance.

- At lower polymer viscosities, membranes often show finger-like porous structures.

- At higher polymer viscosities, membranes shift to sponge-like structures.

- Increased dope solution viscosity slows the coagulation front, hindering solvent and non-solvent penetration. This influences phase separation type and membrane skin layer porosity.

The draw ratio, which affects fiber geometry and morphology, also depends on dope solution viscosity. Lower viscosity allows more fiber stretching during spinning. The spinning process requires careful control of dope viscosity to balance selectivity, productivity, and process stability in hollow fiber spinning machine.

Dope Solution Viscosity Effects

Flow Rate and Spinning Speed

Dope solution viscosity plays a crucial role in determining the flow rate of the dope solution and the spinning speed in hollow fiber spinning machine. When the viscosity of the dope increases, the flow through the spinneret becomes more controlled. This control helps prevent the formation of discontinuous strands, which can occur if the viscosity is too low. Engineers often adjust the polymer concentration and temperature to achieve the desired viscosity. For example, experiments with polyimide hollow-fiber membranes show that stable spinning occurs when the dope viscosity falls within a specific range. The flow rate of the dope solution, typically set at 3.6 or 5.0 g/min at 50 °C, remains stable as long as the viscosity stays within the optimal window. The bore fluid composition also affects viscosity and phase inversion, which in turn influences the final fiber morphology. Salt solutions in the bore fluid can lower viscosity slightly and speed up polymer precipitation, changing the structure of hollow fiber membranes.

| Dope Viscosity (mPa·s) | Dope Extrusion Rate (g/min) | Spinning Stability | Fiber Morphology Impact |

|---|---|---|---|

| Low (<10,000) | 3.6–5.0 | Unstable | Discontinuous strands |

| Optimal (10,000–60,000) | 3.6–5.0 | Stable | Uniform, defect-free |

| High (>60,000) | 3.6–5.0 | Difficult to extrude | Thick, dense fibers |

The table above summarizes how dope solution viscosity and dope extrusion rate interact to affect spinning stability and fiber morphology. Operators must monitor both parameters to ensure consistent hollow fiber membrane production.

Draw Ratio and Fiber Dimensions

The draw ratio, defined as the take-up speed divided by the extrusion speed, directly influences the dimensions and structure of hollow fiber membranes. Changes in dope solution viscosity affect the draw ratio by altering the ease with which the fiber stretches as it exits the spinneret. Higher viscosity reduces the mutual diffusion between solvent and non-solvent, slowing the solidification process and promoting the formation of sponge-like structures in hollow fiber membranes. When the draw ratio increases, the outer and inner diameters of the fibers decrease, resulting in denser and more compact hollow fiber membranes.

- Increasing dope solution viscosity:

- Reduces the flow rate of the dope solution through the hollow fiber spinneret.

- Promotes sponge-like structures in hollow fiber membranes.

- Delays non-solvent intrusion, preventing macro-void formation.

- Enhances polymer chain orientation and packing, leading to denser hollow fiber membranes.

The extensional viscosity of the spinning dope rises with extension rate, which contrasts with its shear thinning behavior. This extension hardening improves the mechanical properties of hollow fiber membranes and leads to smaller fiber dimensions at higher draw ratios. Additives such as PEG can further modify dope viscosity and precipitation rates, influencing whether finger-like or sponge-like structures form near the surface of hollow fiber membranes. The timing of contact between the bore fluid and the dope solution, controlled by viscosity and spinning conditions, determines the formation of the inner and outer skin layers in hollow fiber membranes.

Membrane Selectivity and Productivity

Dope solution viscosity also impacts the selectivity and productivity of hollow fiber membranes. The typical viscosity range for dope solutions in hollow fiber spinning machine falls between 10,000 and 60,000 mPa·s. Within this range, operators can balance the trade-off between membrane selectivity and productivity. Higher dope viscosity slows the phase inversion process, resulting in thicker skin layers and denser hollow fiber membranes. These changes increase selectivity but may reduce permeability and overall productivity.

Membrane performance depends on achieving the right balance between selectivity and permeability. High viscosity dope solutions produce hollow fiber membranes with improved separation efficiency but lower permeation rates. Lower viscosity dope solutions, on the other hand, yield hollow fiber membranes with higher permeability but reduced selectivity. Environmental factors such as temperature and humidity also affect dope solution viscosity. Higher temperatures lower viscosity, which can change the pore structure and surface morphology of hollow fiber membranes. Increased humidity can reduce the maximum spinning rate and decrease fiber diameter, further influencing membrane performance.

Note: Operators must carefully monitor dope viscosity, dope extrusion rate, and environmental conditions to optimize hollow fiber membrane production. Adjusting these parameters ensures that hollow fiber spinning machine produces membranes with the desired balance of selectivity, permeability, and productivity.

Polymer Properties and Machine Output

Polymer Concentration and Molecular Weight

Polymer concentration and molecular weight play a central role in the performance of hollow fiber membrane spinning machine. Increasing polymer concentration in the dope solution raises viscosity, which requires longer degassing times before spinning. Higher viscosity affects the dope flow rate, influencing the morphology of hollow fiber membranes. Membranes formed from higher viscosity solutions show changes in porosity, pore size, fiber diameter, and wall thickness. When the dope flow rate increases, thicker and more compact outer skin layers develop due to shear effects at the hollow fiber spinneret. These changes improve membrane flux and overall performance, directly impacting the output quality and efficiency of hollow fiber spinning machines.

| Polymer Molecular Weight (Mw, g/mol) | Viscosity of 20 wt.% PPSU Solution (mPa·s) |

|---|---|

| ~13,400 | 340 |

| ~23,500 | (intermediate value) |

| ~39,500 | (intermediate value) |

| 102,000 | 12,100 |

Viscosities above 10,000 mPa·s are necessary for successful hollow fiber membrane formation. Only high molecular weight polymers produce solutions with sufficiently high viscosity for hollow fiber membranes. Lower molecular weight polymers yield viscosities too low for spinning. The addition of PEG400 increases viscosity, enabling membrane formation at lower polymer concentrations. Both polymer concentration and molecular weight control dope solution rheology, which is critical for hollow fiber membranes.

Viscoelasticity and Solidification Rate

The viscoelastic behavior of polymer solutions during spinning strongly influences hollow fiber membranes. Viscoelasticity affects molecular orientation, phase inversion, and gelation kinetics. Changes in viscoelasticity alter relaxation time and gelation mechanisms, which determine the final structure of hollow fiber membranes. During extrusion, viscoelastic properties shape fiber morphology, including hollowness, solidification, and molecular orientation. Hollow fibers solidify faster than solid fibers of the same linear density, which impacts molecular orientation and crystallization. Strong viscoelasticity can cause circumferential instability, leading to non-uniform wall thickness and non-circular cross-sections in hollow fiber membranes. The solidification rate of polymer solution and viscoelasticity together control the uniformity and mechanical properties of hollow fiber membranes.

| Aspect | Evidence Linking Viscoelasticity to Fiber Morphology |

|---|---|

| Polymer behavior during extrusion | Viscoelastic properties influence fiber morphology including hollowness, solidification, and molecular orientation |

| Solidification rate | Hollow fibers solidify faster than solid fibers of the same linear density, affecting molecular orientation and crystallization |

| Molecular orientation | Hollow fibers show higher amorphous orientation due to higher take-up stress linked to viscoelastic effects |

| Processing parameters | Spinneret die geometry, polymer melt rheology (including viscoelasticity), and spinning conditions affect hollowness and fiber morphology |

Impact on Fiber Morphology

Polymer properties such as concentration, molecular weight, and architecture determine the morphology, uniformity, and production efficiency of hollow fiber membranes. Low polymer concentration causes beads, while optimal concentration yields continuous, bead-free hollow fiber membranes. Higher molecular weight increases chain entanglement, supporting stable fiber formation and reducing droplet formation. Viscosity, linked to both concentration and molecular weight, controls fiber thickness and solvent evaporation. Excessive viscosity can hinder solvent evaporation, causing thicker hollow fiber membranes, while low viscosity leads to poor fiber formation. The solidification rate of polymer solution, affected by temperature and humidity, influences fiber diameter and membrane morphology. Low humidity favors uniform, continuous hollow fiber membranes, while high humidity can reduce fiber quality. Polymer molecular architecture also affects dope rheology and phase inversion, which are critical for membrane morphology and performance. Optimizing these properties balances permeability, selectivity, and mechanical stability in hollow fiber membranes, ensuring high-quality output from spinning machines.

Hollow Fiber Spinning Machine Parameters

Process Stability

Process stability in hollow fiber spinning depends on the interaction between machine parameters and dope solution viscosity. The flow rate and spinning speed respond quickly to changes in viscosity. When the dope solution viscosity decreases, the spinning speed increases by up to 1.4 times, which shortens residence time in the air gap and affects solvent evaporation. The spinneret must maintain a consistent extrusion rate to prevent flow instabilities. Computational Fluid Dynamics studies show that uneven viscosity can cause bulk flow and irregular wall formation inside the spinneret. These instabilities reduce the strength and uniformity of hollow-fiber membranes. Operators often keep bore fluid flow rate, air gap, and extrusion pressure constant to isolate the effect of viscosity. Modeling studies highlight that the dope extrusion rate, air gap length, and coagulation bath temperature all influence membrane rejection and morphology. Maintaining a 1:1 ratio of dope extrusion rate to bore fluid flow rate produces stable, perfectly rounded hollow fiber membranes.

Defect Formation

Defect formation in hollow fiber membranes often results from improper control of dope solution viscosity and machine parameters. Flow instabilities inside the spinneret, caused by the rheological properties of the dope, can lead to uneven wall thickness and weak membrane structure. Shear rate and flow rate interactions affect molecular orientation and pore formation, which impacts mechanical strength and permeability. Variations in air gap distance change membrane morphology, with higher air gaps producing thinner, more porous skin layers. If the dope solution viscosity is too low, discontinuous strands and macrovoids may form, reducing membrane quality. High viscosity can make extrusion difficult, resulting in thick, dense hollow fiber membranes with reduced permeability. Operators must monitor viscosity and adjust spinning conditions to prevent defects and stabilize the process.

Optimization Strategies

Engineers use several strategies to optimize dope solution viscosity and processing conditions in hollow fiber spinning machine:

- Synchronize polymer extrusion speed and take-up speed to improve efficiency.

- Adjust bore fluid pressure to control membrane diameter and wall thickness.

- Vary air gap distance to influence outflow velocity and wall thickness.

- Use low-toxic diluent systems like PEG300/TEG to lower spinning temperature and prevent polymer decomposition.

- Control diluent ratio to manage phase separation and membrane morphology.

- Adjust polymer concentration and cooling rate to impact membrane structure.

- Optimize bore liquid composition, such as increasing propylene carbonate ratio, to enhance inner surface porosity and water permeability.

- Apply co-extrusion with triple-orifice spinnerets to regulate membrane pore size and surface structure.

- Select extrusion solvents with appropriate viscosity to control solvent penetration and membrane microstructure.

The table below summarizes a case study on optimizing viscosity in hollow fiber spinning operations:

| Parameter | Effect of Increasing PSf Concentration | Effect of Additives (PVP, PEG400) |

|---|---|---|

| Viscosity | Increases from 740 to 26,420 mPa·s | 1.5–3× higher viscosity than pure PSf-NMP |

| Membrane Morphology | Denser structures, smaller finger-like channels | PVP: more transport channels; PEG400: denser layers, smaller pores |

| Mechanical Strength | Tensile strength up to ~15 MPa | Additives reduce strength at low PSf, maintain at high PSf |

| Water Permeability | Decreases with higher PSf | Additives increase permeability at low PSf, decrease at high PSf |

| Process Parameters | Increases holding time, decreases lifting velocity | Controls wall thickness and morphology |

These strategies help engineers produce hollow fiber membranes with controlled geometry, improved permeance, and stable performance.

Conclusion

Controlling viscosity remains essential for producing high-quality hollow fiber membranes. Researchers find that increasing polymer concentration or using high molecular weight additives raises viscosity, which shapes membrane morphology and boosts membrane performance. Operators should monitor temperature and adjust spinning parameters to maintain optimal viscosity, ensuring consistent permeability and selectivity. Balancing these factors supports stable production, reduces defects, and enhances the overall effectiveness of membranes in industrial applications.

Tip: Real-time monitoring of viscosity and phase inversion helps maintain process stability and maximize membrane permeability.

FAQ

What Is the Optimal Viscosity Range for Hollow Fiber Spinning?

Operators usually maintain dope solution viscosity between 10,000 and 60,000 mPa·s. This range supports stable spinning, uniform fiber formation, and consistent membrane performance.

How Does Polymer Viscosity Affect Membrane Selectivity?

Higher polymer viscosity increases membrane selectivity. Thick skin layers form, which improve separation efficiency. Lower viscosity produces membranes with higher permeability but reduced selectivity.

What Are Common Defects Caused by Incorrect Viscosity?

Low viscosity can cause discontinuous strands and macrovoids. High viscosity may lead to thick, dense fibers with poor permeability. Operators monitor viscosity to prevent these defects.

How Can Engineers Adjust Viscosity During the Melt Spinning Process?

Engineers change polymer concentration, molecular weight, and temperature to control viscosity. Additives like PEG also help adjust viscosity for optimal fiber formation during the melt spinning process.

Why Is Real-Time Viscosity Monitoring Important?

Real-time viscosity monitoring helps operators maintain process stability. Quick adjustments prevent defects and ensure consistent membrane quality throughout production.